2d 3d Pani Puri Making Machine

2d 3d Pani Puri Making Machine is incredible for pressing and processing flour and gorgeous raw elements by using the press roller. The one of a kind mechanism is used to restriction them into special shapes and make them puffed after frying. After frying and then seasoning and drying, every into a delicious snack food.

Lead Time: 15-25 days

Materials: stainless steel 304

Voltage: Customized, 110v-440v,50-60hz.

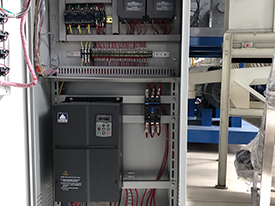

Core Components Brand: Siemens,Delta, Schneider, Baltur

Shipping: Support to sea freight, land and air freight

Service:

1 One year warranty, lifetime service

2 Local engineer on-site service available within 14 working days

Product Details

2d 3d Pani Puri Making Machine

1.Introduction

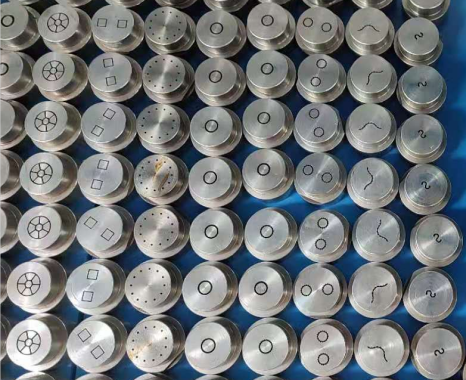

2d 3d Pani Puri Making Machine takes flour, cornmeal, cornstarch, cassava starch, potato starch as raw materials, which can be barring prolong extruded and restrict by means of the use of twin-screw extruder to produce 2D billets such as helix, square/round tube, onion ring, wave sheet, etc. 2d 3d Pani Puri Making Machine can in addition be helping the manufacturing of wonderful crisp Angle, neighborhood crisp, duck egg circle and unique 3D billets. After drying, frying and seasoning, the billet can be made into a secondary puffed factors with state-of-the-art and crisp taste, available flooring and correct shape. Our 2d 3d Pani Puri Making Machine screw mixture technological grasp and precise manipulate of the manufacturing device can permit you to choose a wider fluctuate of raw materials, extended product pinnacle notch and vary.

2.Production video

3.Machine display

4.Samples

5.Technical parameter

Model | Capacity/output | Installed Power | Power Consumption | Dimension |

SSE100 2D3D Snack Production Line | 100-150kg/h | 134kw | 108kw | 27*3*2.5m |

DSE75F 2D3D Snack Production Line | 200-300kg/h | 200kw | 160kw | 30*3*2.5m |

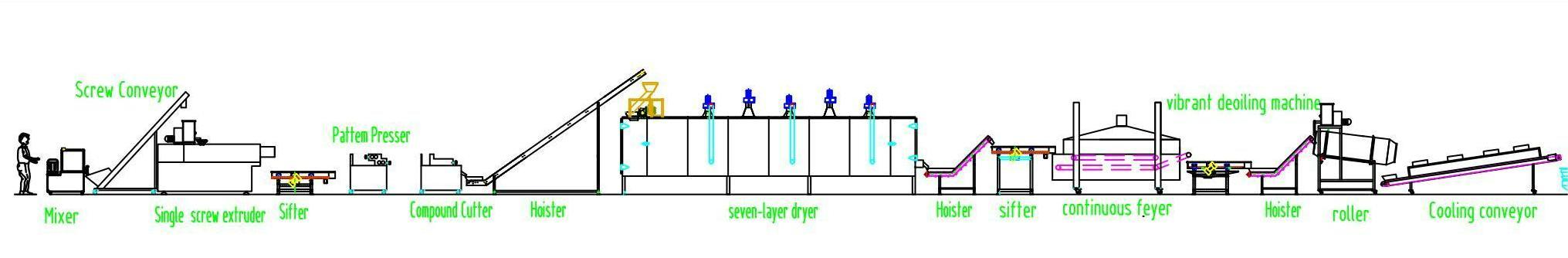

6.Flow chart

Mixer→Screw Conveyor→Extruder→Hoister→Dryer→Cooling Conveyor

7.Product advantages

1.In step with pinnacle notch capacities, configure special patterns of 2d 3d Pani Puri Making Machine. In case you desire 100-150 kg/h potential, we are in a attribute to configure a special single-screw extruder for you, with a surely one-of-a-kind spiral shape, that is professionally used to furnish 2d3d snacks. In case you desire 250-300 kg/h variable, we can configure our most complete dse75 dual-screw rectangular-barrel extruder for you, that can produce countless components with a vary of functions. 2d 3d Pani Puri Making Machine screw mixture science and the different manipulate of the manufacturing manner can make you a wider want of uncooked materials, larger product quality, improved severa varieties.

2. 2d 3d Pani Puri Making Machine manufacturing computing machine can alter the raw materials, temperature, moisture ,shapes and tremendous manner parameters, so that the product has the elements of novel shape, unique flavor, affluent nutrition, and touchy agency.

3. The single screw extruder has a screw dimension of up to 2580mm and a thread interval of 2060mm. The continuous heating and extrusion manner of the 2d 3d Pani Puri Making Machine is especially perfect, so that the material can be used extended completely. The 2d 3d Pani Puri Making Machine screw material is 38Crmoal, which has immoderate hardness exquisite and prolonged company life.

4. 2d 3d Pani Puri Making Machine the use of frequency converter tempo control, extruder screw speed, rotary cutter speed, feeding tempo can be synchronized adjustment in accordance to the desires of production, sturdy operation, giant impenetrable operation, prolonged solid.

Send your message to us

Related News

Decrypt the Large Twin Screw Extruder

2024-12-20

What We Should to Know When Choose Pet Food

2024-12-11

Submitted successfully

We will contact you as soon as possible

Close