2D3D Pellet Snack Extruder Machine

Lead Time: 15-25 days

Materials: stainless steel 304

Voltage: Customized, 110v-440v,50-60hz.

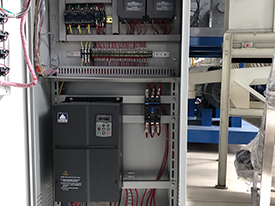

Core Components Brand: Siemens,Delta, Schneider, Baltur

Shipping: Support to sea freight, land and air freight

Service:

1 One year warranty, lifetime service

2 Local engineer on-site service available within 14 working days

Product Details

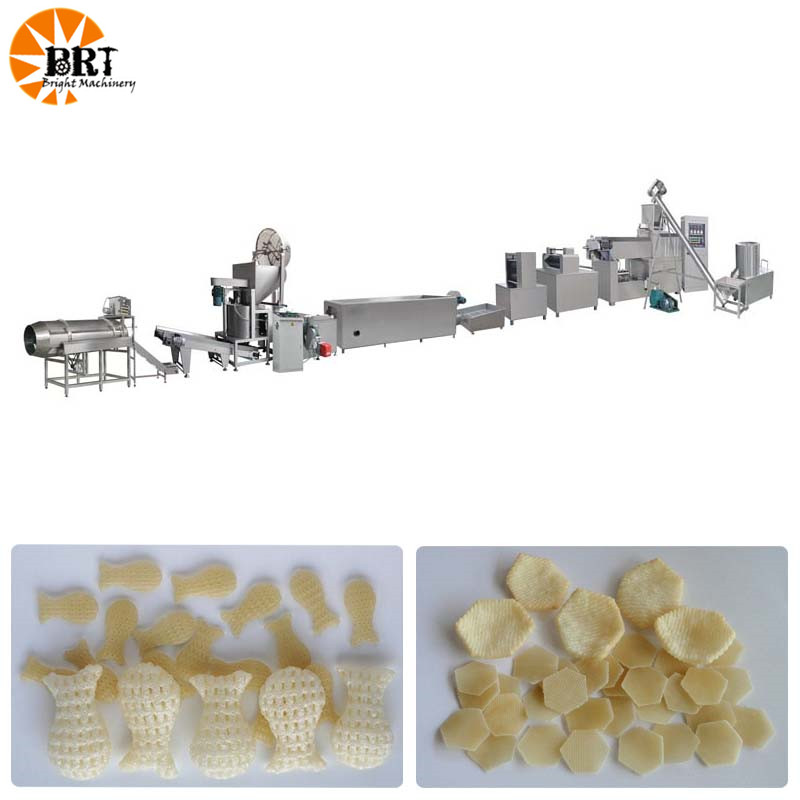

2D3D Pellet Snack Extruder Machine

1.Introduction

The automated 2d3d snack manufacturing line makes powdered uncooked materials which includes corn flour into 2d3d snack through the technique of blending,extruding,drying and cooling. the same production line can produce 2d3d snacks of diverse shapes and sizes. at the identical time, the same 2d3d snack may be matched with exceptional system manufacturing strains according to special capability.

2.Production video

3.Machine display

4.Samples

5.Technical parameter

Model | Capacity/output | Installed Power | Power Consumption | Dimension |

SSE100 2D3D Snack Production Line | 100-150kg/h | 134kw | 108kw | 27*3*2.5m |

DSE75F 2D3D Snack Production Line | 200-300kg/h | 200kw | 160kw | 30*3*2.5m |

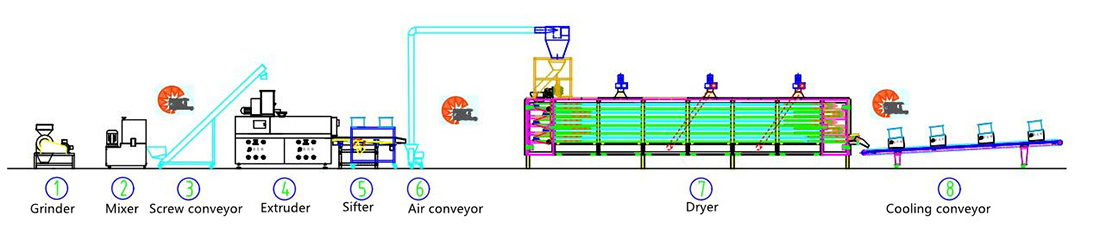

6.Flow chart

Mixer→Screw Conveyor→Extruder→Hoister→Dryer→Cooling Conveyor

7.Product advantages

1.In step with exceptional capacities, configure distinctive styles of extruders. in case you need 100-150kg/h potential, we are able to configure a unique single-screw extruder for you, with a completely unique spiral shape, that is professionally used to provide 2d3d snacks. in case you need 250-300kg/h variable, we can configure our maximum comprehensive dse75 dual-screw rectangular-barrel extruder for you, that can produce numerous foods with assorted functions.

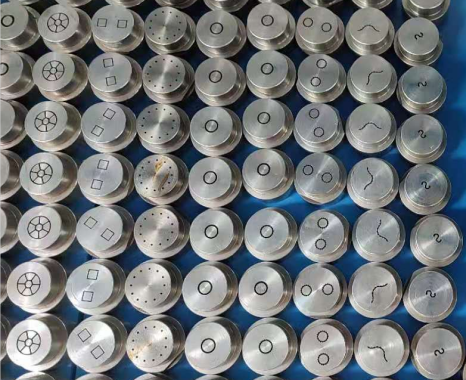

2.The production device can alter the uncooked materials, temperature, moisture ,shapes and other manner parameters, so that the product has the characteristics of novel shape, particular flavor, wealthy nutrition, and sensitive agency.

3.The screw period of the unmarried-screw extruder is as excessive as 2580mm, and the thread duration is 2060mm. the continuous heating and extrusion technique of the cloth is extra complete, in order that the material may be more absolutely applied. the screw material is 38crmoal, which has higher great and longer provider existence.

4.Using the frequency conversion pace regulation machine, the feeding speed, the rotary slicing speed, and the jogging speed of the host may be adjusted in step with the precise manufacturing needs, with strong operability, smoother and greater solid operation.

Send your message to us

Related News

Decrypt the Large Twin Screw Extruder

2024-12-20

What We Should to Know When Choose Pet Food

2024-12-11

Submitted successfully

We will contact you as soon as possible

Close