2D3D Pellet Snack Machine

Lead Time: 15-25 days

Materials: stainless steel 304

Voltage: Customized, 110v-440v,50-60hz.

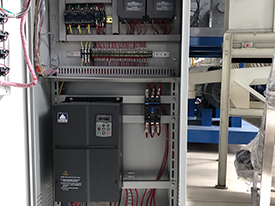

Core Components Brand: Siemens,Delta, Schneider, Baltur

Shipping: Support to sea freight, land and air freight

Service:

1 One year warranty, lifetime service

2 Local engineer on-site service available within 14 working days

Product Details

1.Introduction

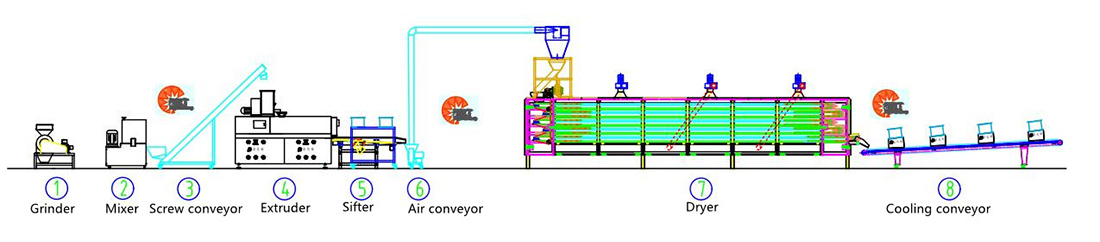

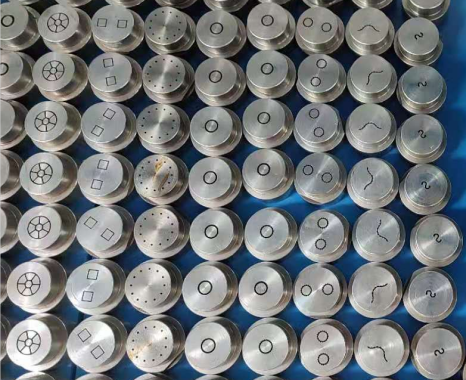

The automatic 2D3D snack production line makes powdered raw materials such as corn flour into 2D3D snack through the process of mixing,extruding,drying and cooling. The same production line can produce 2D3D snacks of various shapes and sizes. At the same time, the same 2D3D snack can be matched with different machine production lines according to different capacity.

2.Production video

3.Machine display

4.Samples

5.Technical parameter

Model | Capacity/output | Installed Power | Power Consumption | Dimension |

SSE100 2D3D Snack Production Line | 100-150kg/h | 134kw | 108kw | 27*3*2.5m |

DSE75F 2D3D Snack Production Line | 200-300kg/h | 200kw | 160kw | 30*3*2.5m |

6.Flow chart

Mixer→Screw Conveyor→Extruder→Hoister→Dryer→Cooling Conveyor

7.Product advantages

1.According to different capacities, configure different types of extruders. If you need 100-150kg/h capacity, we will configure a special single-screw extruder for you, with a unique spiral structure, which is professionally used to produce 2d3d snacks. If you need 250-300kg/h variable, we will configure our most comprehensive DSE75 twin-screw square-barrel extruder for you, which can produce various foods with diversified functions.

2.The production equipment can adjust the raw materials, temperature, moisture ,shapes and other process parameters, so that the product has the characteristics of novel shape, unique taste, rich nutrition, and delicate organization.

3.The screw length of the single-screw extruder is as high as 2580mm, and the thread length is 2060mm. The continuous heating and extrusion process of the material is more comprehensive, so that the material can be more fully utilized. The screw material is 38CrMoAl, which has better quality and longer service life.

4.Using the frequency conversion speed regulation system, the feeding speed, the rotary cutting speed, and the running speed of the host can be adjusted according to the specific production needs, with strong operability, smoother and more stable operation.

Send your message to us

Related News

Decrypt the Large Twin Screw Extruder

2024-12-20

What We Should to Know When Choose Pet Food

2024-12-11

Submitted successfully

We will contact you as soon as possible

Close