2D3D Snack Pellet Making Machine1.IntroductionThe automated 2d3d snack manufacturing line makes powdered raw materials including corn flour into 2d3d snack via the technique of mixing,extruding,drying and cooling. the identical production line can produce 2d3d snacks of numerous sizes and patterns.

Contact Now

2D3D Pellet Snack Extruder Machine1.IntroductionThe automated 2d3d snack manufacturing line makes powdered uncooked materials which includes corn flour into 2d3d snack through the technique of blending,extruding,drying and cooling. the same production line can produce 2d3d snacks of diverse shapes and sizes.

Contact Now

2D3D Pellet Snack Machine 1.IntroductionThe automatic 2D3D snack production line makes powdered raw materials such as corn flour into 2D3D snack through the process of mixing,extruding,drying and cooling. The same production line can produce 2D3D snacks of various shapes and sizes.

Contact Now

2D3D Pellet Snack Production Line1.IntroductionThe automatic 2d3d snack production line makes powdered raw substances including corn flour into 2d3d snack through the system of mixing,extruding,drying and cooling. the identical production line can produce 2d3d snacks of numerous styles and sizes.

Contact Now

2D3D Pellet Snack Making Machine1.IntroductionThe automatic 2D3D snack production line makes powdered raw materials such as corn flour into 2D3D snack through the process of mixing,extruding,drying and cooling. The same production line can produce 2D3D snacks of various shapes and sizes.

Contact Now

2D3D Pellet Snack Extruder1.IntroductionThe automatic 2d3d snack production line makes powdered uncooked materials together with corn flour into 2d3d snack thru the machine of blending,extruding,drying and cooling. the same production line can produce 2d3d snacks of severa patterns and sizes.

Contact Now

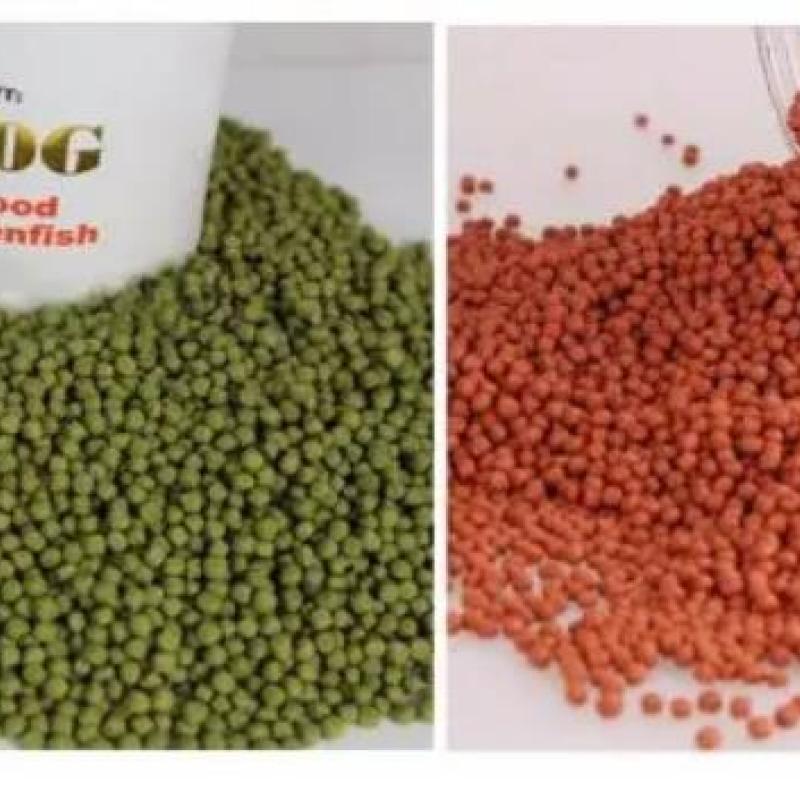

Pet Dog Food Pellet Extruder Machine1 IntroductionPet Dog Food Pellet Extruder Machine is a very frequent manufacturing line for many years that can produce components for many kinds of pets, such as dogs, cats, birds, etc. The manufacturing line adopts extrusion manner to desktop powdery raw elements into components particles of a differ of shapes and sizes to meet one of a structure manufacturing needs.

Contact Now

Indian 3d Snack Pellet Pani Puri Making Machine1.IntroductionIndian 3d Snack Pellet Pani Puri Making Machine line takes flour, cornmeal, cornstarch, cassava starch, potato starch as raw materials, which can be directly extruded and cut by twin-screw extruder to produce 2D billets such as helix, square/round tube, onion ring, wave sheet, etc. Indian 3d Snack Pellet Pani Puri Making Machine can also be supporting the production of wonderful crisp Angle, network crisp, duck egg circle and other 3D billets.

Contact Now

3d Pellet Food Machine1.Introduction3d Pellet Food Machine takes flour, cornmeal, cornstarch, cassava starch, potato starch as uncooked materials, which can be barring lengthen extruded and prevent via ability of the use of twin-screw extruder to produce 2D billets such as helix, square/round tube, onion ring, wave sheet, etc. 3d Pellet Food Machine can in addition be supporting the manufacturing of gorgeous crisp Angle, local crisp, duck egg circle and special 3D billets.

Contact Now

Dry Floating Fish Feed Pellet Extruder Machine1 Introduction High-protein extruded feed pellets, high-protein content material, fish develop quickly, absorb well, and feed waste is minimal, and fish excrement does less harm to high-quality water, and may be recycled and utilized to increase ecological agriculture.

Contact Now

Fish Feed Pellet Double Screw Extruder 1 IntroductionUncooked to cooked, shallow to deep processing, from the original fish and shrimp swamped without delay to feeding, to the later matured pellet feeding, to the current nutritional ratio scientific feeding, the types of fish feed have evolved. For small and medium aquaculture farms and character fisheries, the extruded fish feed equipment and device production line specializes in the production of various types and specifications of extruded aquatic fish feed.

Contact Now

Dry Dog Food Pellet Machine Extruder1 IntroductionDog food is specially provided for pets, little animals feed, between human food and ancient placental mammal and poultry feed animal food, chiefly for all types of pets to supply basic life insurance, growth and health needed nutrients. it's the benefits of comprehensive nutrition, high digestion and absorption rate, scientific formula, quality customary, convenient feeding and use, and may forestall some diseases.

Contact Now

Bread Crumb Extruder Machine1.Introduction The producing line makes use

Contact Now

Dog Food Pellet Making Line Machine1 IntroductionDog Food Pellet Making Line Machine line makes use of grain pellets or powders as uncooked substances and consists of many processes. Mixing, extruding, drying, flavoring and cooling etc.

Contact Now

Cat Food Pellet Making Machine1.Introduction The Cat Food Pellet Making Machine makes powdered uncooked property which consists of corn flour into pups elements with the aid of way of the method of blending,extruding,drying,flavoring and cooling. the Automatic Pet Food Kibbles Production can produce domestic doggies factors of a fluctuate of sizes and styles.

Contact Now

Dog Food Pellet Making Line1 IntroductionThis pet food production line uses grain pellets or powders as raw materials and includes many processes. Mixing, extruding, drying, flavoring and cooling etc.

Contact Now

Automatic Pet Feed Pellet Machine1.Introduction The Automatic Pet Feed Pellet Machine makes powdered uncooked property which consists of corn flour into puppies substances with the useful resource of the method of blending,extruding,drying,flavoring and cooling. Automatic Pet Feed Pellet Machine can produce doggies substances of increased than a few sizes and styles.

Contact Now

Dog Food Products Extruder 1.IntroductionDog Food Products Extruder ,The computerized massive workable canines ingredients manufacturing line makes powdered raw resources such as corn flour into canines foods through the manner of mixing,extruding,drying,flavoring and cooling. The equal manufacturing line can produce dogs foods of a range of shapes and sizes.

Contact Now

Artificial Rice Extruder Machine1.IntroductionUsing Artificial Rice Extruder Machine, the damaged rice (damaged rice and fallen rice embryo) might also be restored, restored or processed into rice grains which can be almost the identical as day-to-day entire rice, or in step with the requirements of clinical meals plan, a few herbal nutritional vitamins alongside with more than a few sorts miscellaneous grains are blended together in a positive share to make excessive-nutrition rice and right now rice with the same cooking general overall performance and cooking approach (with taste) as everyd

Contact Now

Commercial Dog Food Pellet Making Machine1 IntroductionDog food is specially provided for pets, small animals feed, between human food and traditional livestock and poultry feed animal food, mainly for all kinds of pets to provide basic life assurance, growth and health required nutrients.

Contact Now

Commercial Dog Food Pellet Making Machine1 IntroductionDog food is specially provided for pets, small animals feed, between human food and traditional livestock and poultry feed animal food, mainly for all kinds of pets to provide basic life assurance, growth and health required nutrients.

Contact Now

Fish Feed Floating Pellet Machine1.IntroductionMain factors of Fish Feed Floating Pellet Machine:1. Fish Feed Floating Pellet Machine all undertake frequency conversion tempo rules system, which has sturdy power, regular operation, electrical energy saving, immoderate aquatic manufacturing efficiency, sturdy and extended lasting Fish Feed Floating Pellet Machine, low failure rate, and reachable operation and maintenance.2.

Contact Now

Automatic Fish Feed Pellet Machine1.IntroductionAutomatic Fish Feed Pellet Machine: When combined uncooked substances are squeezed via double screw fish shrimp feed pellet computer in excessive temperature and excessive strain environment, the starch shape in the uncooked substances modifications and will become effortlessly absorbed nutrients. Automatic Fish Feed Pellet Machine is extruded via the feed mould and fish shrimp feed pellet computing device adjusted the pace of the rotary slicing motor till the feed particles of the equal measurement and size are regulated.

Contact Now

Commercial Animal Pet Fish Feed Pellet Extruder 1 IntroductionThe expanded aquatic feed can float on the water surface for a long time, which is convenient for feeding and management and labor saving; Generally, the powder produced by expanded feed is less than 1%, and the floating time of high-quality floating fish feed can generally reach 2 hours.2 Production Video3 Machine Display4 Sample5 Technical ParameterModelInstall power(kw)Actuall consumption(kw)CapacitySize(mm)DSE-65 production line8056-64100-150 kg/h21000*1500*3000DSE-70 production line11682-93200-250 kg/h21000*1500*3000DSE-75

Contact Now