Puff Bread Crumbs Making Machine

Puff bread crumbs making machine of acicular round flake bread bran is designed based on twin-screw extrusion technology, and puff bread crumbs making machine's quality and operation have reached the strong level in China. The production line has changed the traditional bread bran production process. The production process for mixing, extrusion, cutting, crushing, drying all automated completion. Bread bran is widely used in food additives, used for fried food surface coating, such as: fried chicken, fish, seafood (shrimp), onion ring, etc. Its taste is crispy, delicious and nutritious. Changing the process can produce needle bread crumbs, bread bran, snow powder and other products.

Lead Time: 15-25 days

Materials: stainless steel 304

Voltage: Customized, 110v-440v,50-60hz.

Core Components Brand: Siemens,Delta, Schneider, Baltur

Shipping: Support to sea freight, land and air freight

Service:

1 One year warranty, lifetime service

2 Local engineer on-site service available within 14 working days

Product Details

Puff Bread Crumbs Making Machine

1.Introduction

Puff bread crumbs making machine is a new type of special equipment developed by our company in recent years according to the demand of domestic market. Puff bread crumbs making machine changes the traditional bread bran production technology, and directly expands the raw material by using the extruding principle. Then matched with special molding, screening equipment. Simple process, easy to operate the product shape needle. Granule, flake, etc. are mainly used for all kinds of pastry, fried products, frozen food, etc.

Puff bread crumbs making machine is widely used as food additives, mainly used in western fried steak, fried chicken legs, fish, seafood products, onion rings and other fried coating materials. The puff bread crumbs making machine developed by our company is automatically completed from mixing, extrusion, cutting to breaking and forming, with less personnel, convenient operation, stable and reliable performance, no waste, reduced production cost and improved production efficiency.

2.Production video

3.Machine display

4.Samples

5.Technical parameter

Model | Capacity/output | Installed Power | Power Consumption | Dimension |

100-150kg/h | 76kw | 61kw | 30*3*2.5m | |

DSE70 Bread Crumb Production Line | 200-250kg/h | 200kw | 160kw | 32*3*2.5m |

DSE85 Bread Crumb Production Line | 350-500kh/h | 250kw | 200kw | 36*3*2.5m |

DSE75F Bread Crumb Production Line | 200-400kg/h | 240kw | 198kw | 34*3*2.5m |

DSE95F Bread Crumb Production Line | 400-500kg/h | 280kw | 224kw | 40*3*2.5m |

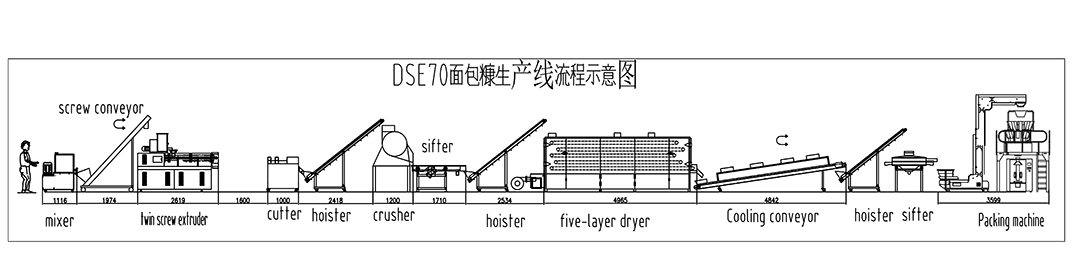

6.Flow chart

Mixer→Conveyor→Extruder→Cutter→Hoister→Crusher→Sifter→Hoister→Dryer→Cooling Conveyor→Hoister→Sifter→Packing Machine

7.Product advantages

Our company provides one-stop services such as plant construction, raw material procurement, product formulation, product testing, equipment installation, production guidance, etc., which almost meets any matters before sales! The company's puff bread crumbs making machine can produce: flake bread crumb, granular bread crumb, Japanese panko, snowflake bread crumb, and other shapes, which can almost meet various market needs! Our company’s puff bread crumbs making machine has reasonable design, strong stability, and the degree of automation has reached the advanced level

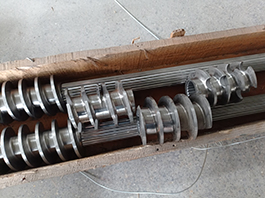

1 The screw adopts alloy steel nitriding treatment, longer life of the screw, individual equipment adopts building block combination structure, can be arbitrarily combined according to different needs

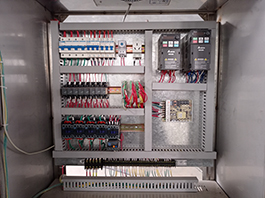

2 Famous brand parts, such as Siemens, Delta, SKF, Baltur and so on, safe and reliable

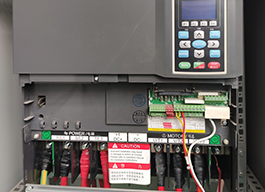

3 Visual automatic temperature control system, to make the temperature control more intuitive, more accurate parameters. Optional Delta or Siemens brand PLC control system

4 The extruder adopts advanced frequency converter speed regulation technology, so that the equipment has strong power, more stable operation, more electricity saving.

Send your message to us

Related News

Decrypt the Large Twin Screw Extruder

2024-12-20

What We Should to Know When Choose Pet Food

2024-12-11

Submitted successfully

We will contact you as soon as possible

Close