Salad Bugle Corn Chips Extruding Production Line

Snack food is also one of fast moving consumer goods, is in people's leisure, rest when the food to eat. Leisure food is gradually becoming a daily consumption of people. With the development of economy and the improvement of consumption level, consumers' demand for the quantity and quality of leisure food is constantly increasing. Packaged snack food is more and more popular because it is convenient and hygienic to eat. Puffed snack food is favored by more and more consumers.

Bugles production line is an automatic fried puffed food equipment developed by Bright Machinery Company according to the demand of domestic and foreign markets. Its operation performance, product quality and process taste are favored by customers.

Lead Time: 15-25 days

Materials: stainless steel 304

Voltage: Customized, 110v-440v,50-60hz.

Core Components Brand: Siemens,Delta, Schneider, Baltur

Shipping: Support to sea freight, land and air freight

Service:

1 One year warranty, lifetime service

2 Local engineer on-site service available within 14 working days

Product Details

Salad Bugle Corn Chips Extruding Production Line

1 Introduction

This manufacturing line should produce bugle structure fried snacks. The principal raw components for the manufacturing of bugles snack are corn starch, rice starch and potato starch. Bugles snack has emerged as a famous food for its delicious and crisp flavor, smooth to raise and consume, enormous utility of uncooked substances, and changeable taste. Our employer adopts new manufacturing procedure line, so that the form of the product is numerous, 3-dimensional experience is powerful, and the agency is delicate, the taste is crisp.

2 Production Video

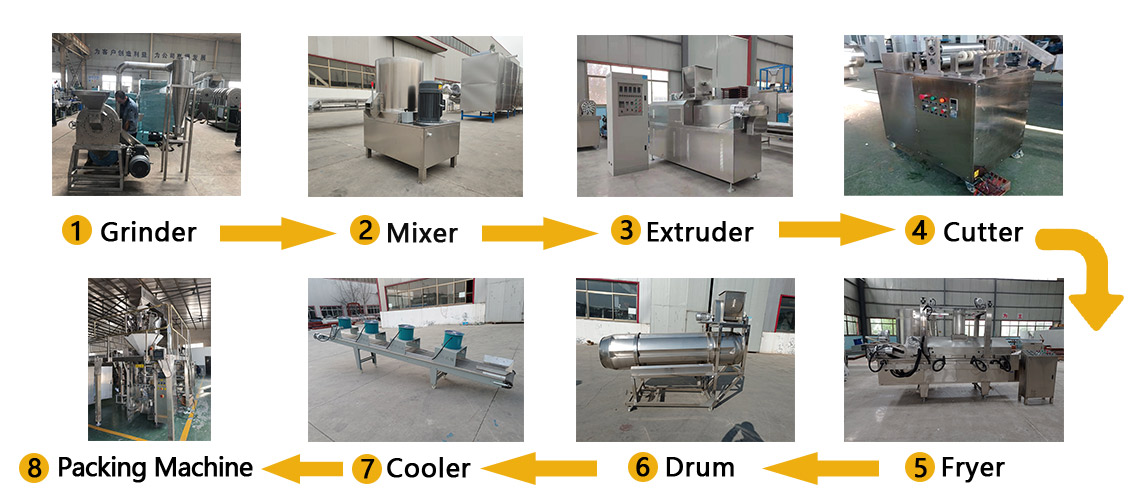

3 Machine Display

4 Samples

5 Technical Parameter

Model | Capacity/output | Installed Power | Power Consumption | Dimension |

DSE65 Fried Bugles Production Line | 100-150kg/h | 120kw | 96kw | 26*3*2.2m |

DSE65F Fried Bugles Production Line | 100-150kg/h | 124kw | 100kw | 26*3*2.2m |

DSE70 Fried Bugles Production Line | 200-250kg/h | 164kw | 132kw | 28*3*2.2m |

DSE70F Fried Bugles Production Line | 200-250kg/h | 130kw | 104kw | 26*3*2.2m |

DSE85 Fried Bugles Production Line | 300-500kg/h | 270kw | 216kw | 32*3*2.2m |

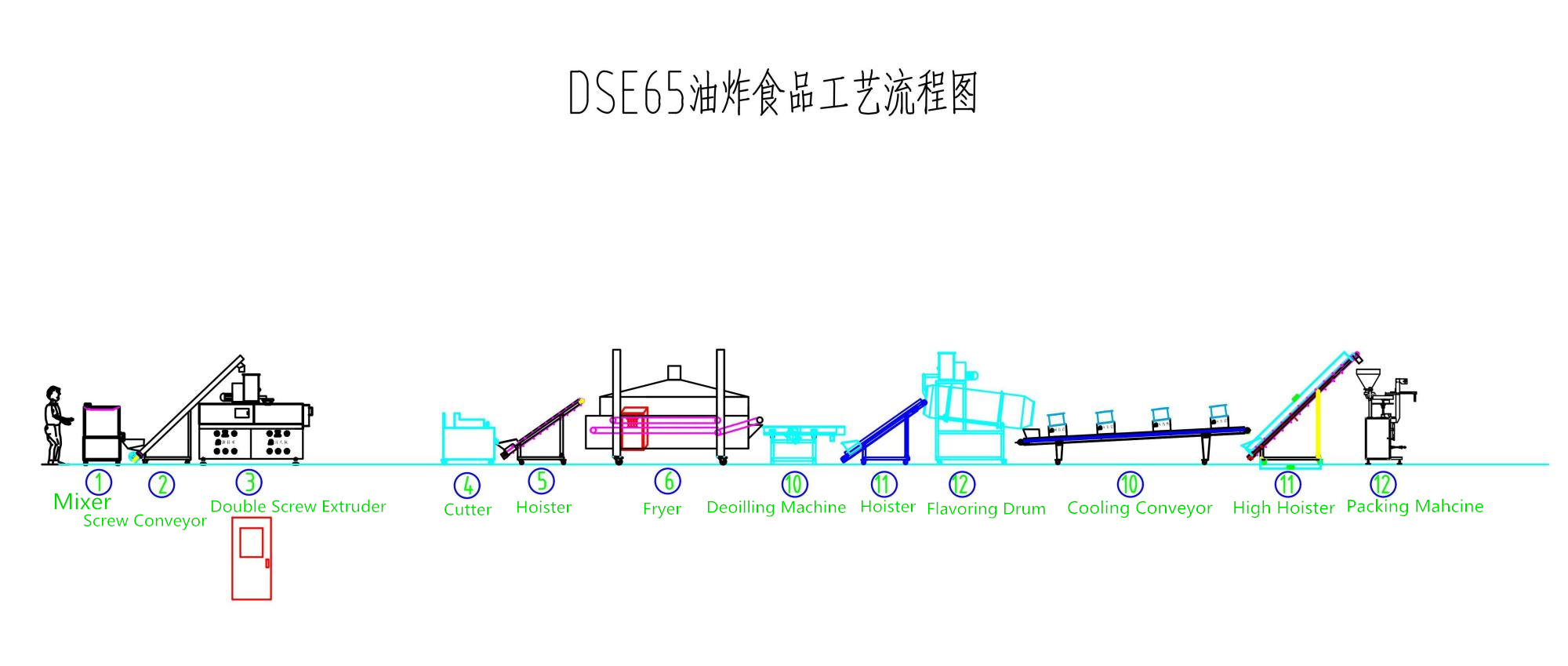

6 Flow Chart

Mixer→Screw Conveyor→Extruder→Cutter→Hoister→Fryer→Deoilling Machine→Hoister→Flavoring Drum→Cooling Conveyor→Hoister→Packing Machine

7 Product Advantage

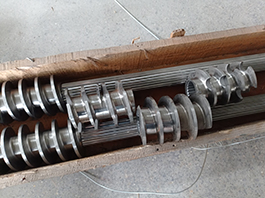

1 The screw is excessive-velocity alloy metal, carburized, with hardness up to hrc 55-65, excessive put on resistance, immoderate hardness, incredible longevity, non-obligatory 38CrMoAl, 12CrMoV, W6Mo5Cr4V2 materials, lengthy carrier lifestyles. some fashions are equipped with a combination screw, which has wider applicability of raw materials. the screw mixture method may additionally be adjusted regular with unique products, and one gadget can also be used for more than one purposes.

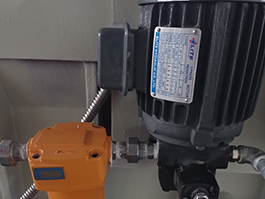

2 Adopt Siemens main motor, Delta inverter, Schneider Omron ABB electrical components, the world's top brands, efficient and stable operation, reliable quality, durable, global accessories, can be directly purchased locally, effectively reducing production cost

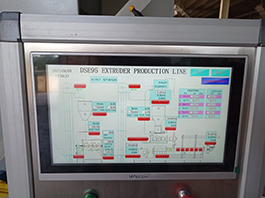

3 The main motor, rotary cutting motor and feeding motor are all controlled by frequency conversion, which can realize soft start and effectively protect the motor, and can adjust the speed according to the product status to produce higher quality products; equipped with PLC touch screen control system, equipment temperature and The speed adjustment is more digital and the control is more precise.

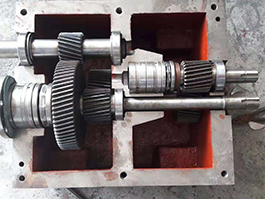

4 Using a new type of box, the box material QT400, good stability. Gear material 20CrNiMoA, carburizing and quenching, hardness HRC58-62, high precision, low noise, long service life; using Japanese NSK, SKF bearings, high precision, long life, stable performance; oil pump motor, forced internal circulation lubrication; condenser, lower The surface temperature of gears and bearings increases the service life; the filter cleans the impurities in the oil, improves the lubrication effect and prolongs the service life

5 The fried food is equipped with a fryer for curing, equipped with an oil filter system to keep the oil clean, ensure product quality and reduce production costs; it is equipped with an oil storage tank, automatic oil replenishment, and internal heating to ensure stable oil temperature and better finished product effect. Zone heating, adjustable heating temperature to meet the needs of different types of products for frying

Send your message to us

Related News

Production Technology of Extruded Snack Food

2024-11-10

Daily Maintenance of Twin Screw Extruder

2024-10-28

Submitted successfully

We will contact you as soon as possible

Close