Corn Curls Cheetos Kurkure Production Line

Corn Curls Cheetos Kurkure is a one of a kind squeeze kind snack that is very crunchy when chewed. they are made of corn grits combined with a share of water and put into a rotary head Corn Curls Cheetos Kurkure Production Line, the place they structure irregular twisted shapes underneath the extrusion and rubbing of two rotary tables, which are then reduce via a cutter into the favored size of product. cheetos can be fried and seasoned, or baked and seasoned.

Lead Time: 15-25 days

Materials: stainless steel 304

Voltage: Customized, 110v-440v,50-60hz.

Core Components Brand: Siemens,Delta, Schneider, Baltur

Shipping: Support to sea freight, land and air freight

Service:

1 One year warranty, lifetime service

2 Local engineer on-site service available within 14 working days

Product Details

Corn Curls Cheetos Kurkure Production Line

1.Introduction

Corn Curls Cheetos Kurkure Production Line is made of corn residue as uncooked material, extruded by way of the host computer into irregular puffed food, after seasoning can be made into extraordinary style products, cherished via consumers. The Corn Curls Cheetos Kurkure Production Line feeds the hopper through vibration and can alter the drift charge of uncooked materials. Corn Curls Cheetos Kurkure Production Line feed screw velocity is managed by way of frequency conversion and can be adjusted arbitrarily. Mechanical tools linkage, to obtain guide manage of the extrusion head clearance,hand wheel manipulate of the desktop base linkage, can make the feeding screw greater without problems into the Corn Curls Cheetos Kurkure Production Line extrusion barrel.

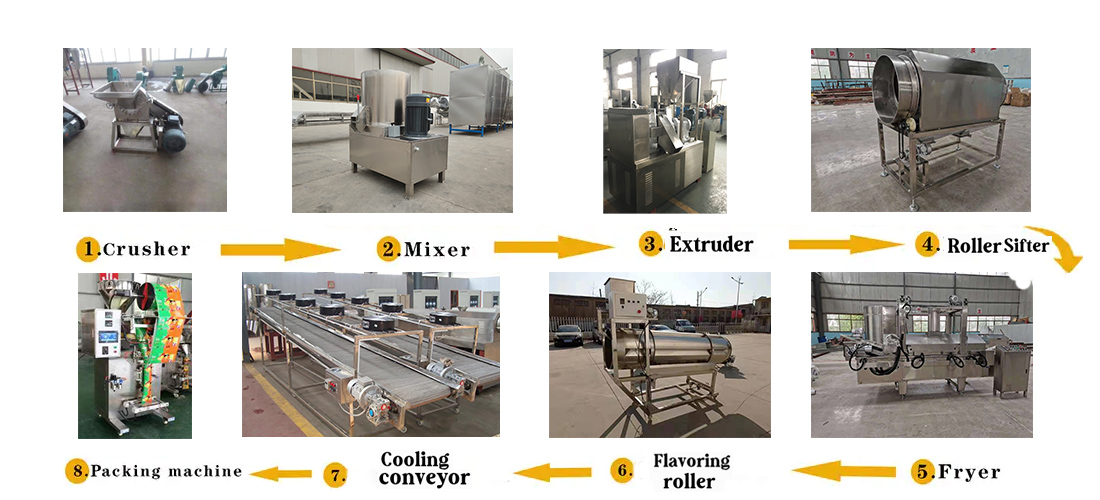

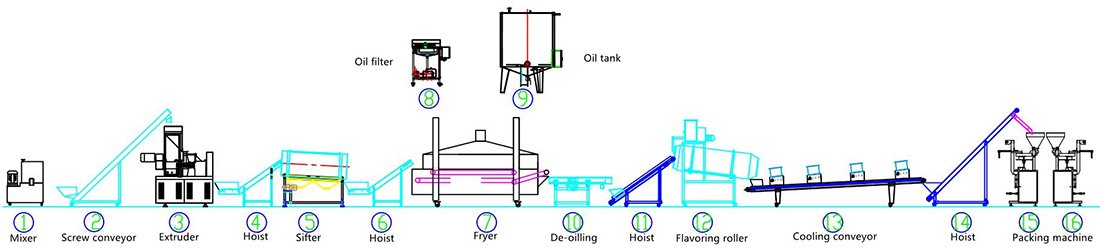

Frying type: ①Flour mixing machine→②Screw conveyor→③Rotary head extruder→④Elevator→⑤Separation cylinder→⑥Vibrating feeder→⑦Continuous fryer→⑧Vibration deoiling machine→⑨Seasoning line

2.Production Video

3.Machine Display

4.Samples

5.Technical Parameter

Model | Install power(kw) | Actuall consumption(kw) | Capacity | Size(mm) |

SSE-76-1 production line | 80 | 56-64 | 100-150 kg/h | 21000*1500*3000 |

SSE-76-2 production line | 100 | 70-80 | 150-200 kg/h | 21000*1500*3000 |

6.Flow Chart

Mixer→Screw conveyor→Extruder→Hoist→Roller screen→Hoistr→Fryer→De-oilling machine→Hoist→Flavoring roller→Cooling conveyor→Hoist→Packing machine

7.Product Advantages

1. The Corn Curls Cheetos Kurkure Production Line is have two wonderful type: frying and baking,can choose out the sort relying on close by market.Both dryer can fryer have one-of-a-kind choice for heating energy.Electric.fuel gas and gas oil.

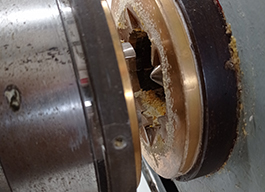

2. The modern rubbing and squeezing technological expertise makes the product crisp and delicious,guarantee the product quality,uses bronze decreasing pan to make the cheetos shape,high stress and immoderate temperature to have a authentic cure effect.

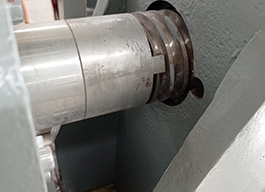

3. Exquisitely designed and specific manipulate gadget of Corn Curls Cheetos Kurkure Production Line, to undertake distinctive cloth and make certain get the demanded puffing effect,the feeding and slicing motor frequency can be conreolled by way of the inverter,adjust in accordance to cloth and last product.

4. The key elements of Corn Curls Cheetos Kurkure Production Line are made of brass, which has correct abrasion resistance,promise prolonged company life,screw cloth 38CrMoAl,HRC 58-62,service life 1.5-2 years, it may also favor to preserve an lousy lot utilization cost

5. Food and cloth contact segment of Corn Curls Cheetos Kurkure Production Line is made by means of way of stainless steel 304 and foods grade PVC,promise the foods safety,the feeding silo and outlet are made through way of stainless steel 304,the silo with inspection window to take a look at the material if favor to feed or give up feeding.

Send your message to us

Related News

Decrypt the Large Twin Screw Extruder

2024-12-20

What We Should to Know When Choose Pet Food

2024-12-11

Submitted successfully

We will contact you as soon as possible

Close