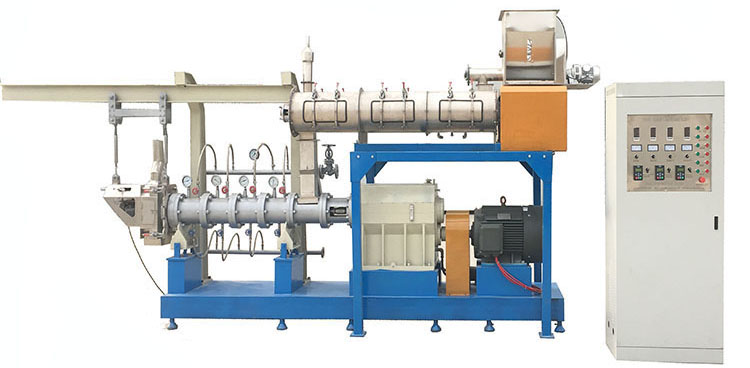

Twin screw extruder

Puffed feed is a kind of bulky and porous feed after puffing treatment. Puffing is a processing technology that changes some physical and chemical properties of materials by using the instantaneous evaporation of water or the expansion characteristics of materials after high temperature and high pressure treatment. It is divided into air puffing and extrusion puffing. After the feed is expanded, the starch will be gelatinized, the long chain structure of protein, fat and other organic substances will be changed into short chain structure, the fiber structure and cell wall will be softened, and the harmful and growth inhibiting factors such as mustard mold in rapeseed meal, cotton mold in cottonseed meal and anti trypsin in soybean meal will be destroyed, making it easier to digest. At the same time, it overcomes the disadvantages of traditional powdery compound feed and pellet feed, such as poor stability in water, fast settling speed, easy loss and waste of feed. The expansion effect is affected by the ratio of raw materials, starch content, moisture content, expansion temperature and other factors. In combination with the expansion characteristics, it should ensure that the starch raw materials in the raw material formula are more than 20%, and the additives should be resistant to high temperature, or the dosage should be increased.

Aquatic expanded fish and shrimp feed

Type:Floating / sinking

Equipment: twin screw aquatic feed expander

01 increase production and efficiency

The expanded aquatic feed can float on the water surface for a long time, which is convenient for feeding and management and labor saving; Generally, the powder produced by expanded feed is less than 1%, and the floating time of high-quality floating fish feed can generally reach 2 hours. Under normal circumstances, compared with the use of powdered feed or other pellet feed, the feed can be saved by 5 ~ 10%, and it is easy to observe and control the feeding, so as to reduce the pollution of powder and residual bait to the water body.

02 applicable scope of expanded feed

In terms of breeding methods, floating fish feed can be used in pond fish culture, rice field fish culture, running water fish culture, cage fish culture, industrialized fish culture and large water surface intensive culture, which has wide applicability,. In terms of breeding species, except for a few benthic fish that are very difficult to domesticate and feed on the water, they can all feed on floating fish feeds, such as bass, snakehead, Guanfu fish, American frog, turtle, turtle, channel catfish and other famous and special varieties, as well as conventionally cultivated Grasscarp, carp, crucian carp and other varieties. It is more convenient and advantageous to breed frogs, perches and other species with special physiological functions with floating feed. Farmers with insufficient breeding experience and extensive management should choose floating feed. Some carnivorous fish that like darkness and fear light need to be domesticated or fed at night when using floating expanded feed. For a few benthic fishes that are very difficult to domesticate and feed on the water surface, it is better not to use floating expanded feed, and heavy or slow sinking expanded feed can be selected.

03 advantages of expanded feed

Denaturation of fat

Extrusion process destroys the cell wall structure of oilseeds and releases the oil. This processing method can improve the utilization of oil. Puffing can also form complex products (lipoprotein) or (lipopolysaccharide) with starch or protein, reduce the content of free fatty acids, inactivate esterase, inhibit the degradation of oil, reduce the rancidity of oil components during product storage and transportation, and is conducive to the long-term preservation of feed.

Increase palatability and digestibility

The expanded feed has small particle size, crispness, and gives off burnt flavor, which improves the palatability. The expanded feed has a loose and disordered structure. This change provides a larger contact area for enzymes, which is conducive to the contact of starch chains, peptide chains and digestive enzymes, and to the digestion and absorption of feed, thus improving the digestibility of feed.

Improve fiber solubility

Extrusion can greatly reduce the content of crude fiber in feed. Through the extrusion technology, due to the instantaneous expansion from high temperature and high pressure to the outlet, the lignin in the intercellular substance and each layer of the cell wall melts, part of the hydrogen bonds break, and the high molecular substances are decomposed into low molecular substances. The original compact structure becomes fluffy, and some digestible substances are released, thus improving the utilization rate of the feed.

It is beneficial to feed storage and prolongs feed shelf life

Under the action of high temperature, high pressure and expansion, the material kills the content of mold, bacteria and fungi in the raw materials, thus improving the hygienic quality of the feed and effectively reducing the occurrence of animal diarrhea, gastroenteritis, dysentery and other diseases.