Automatic Wheat Flakes Making Machine

Breakfast cereals serve as a convenient and fast food which is made by automatic wheat flakes making machine. Nutrient-rich and balanced food was soon available to millions of households. In modern processing, automatic wheat flakes making machine is usually used to complete the full kneading, steaming and granulation of the corn flour mixture after adding water. Corn flakes are a nutritious and balanced breakfast cereal, usually eaten with milk.

Lead Time: 15-25 days

Materials: stainless steel 304

Voltage: Customized, 110v-440v,50-60hz.

Core Components Brand: Siemens,Delta, Schneider, Baltur

Shipping: Support to sea freight, land and air freight

Service:

1 One year warranty, lifetime service

2 Local engineer on-site service available within 14 working days

Product Details

1.Introduction

Automatic wheat flakes making machine with corn flour as an important raw material (can also use oats, buckwheat flour and other different raw material) to produce flake cereals. Automatic wheat flakes making machine is twin screw machinery. overtemperature expanded and extruded by a bolus to make the flakes extremely thin. The special corn dietary fiber and crisp style are loved by the elderly and children, suitable for all kinds of people. It can be boiled with milk for breakfast, or as a snack after being sprayed and baked. Automatic wheat flakes making machine adopts high performance roller and advanced technology, the material is non-stick, the yield is safe, the product thickness is uniform. Automatic wheat flakes making machine has realistic appearance, easy operation and easy maintenance. Automatic wheat flakes making machine is suitable for small and medium-sized, large food processing enterprises, according to the special needs of customers for appropriate configuration.

2.Production Video

3.Machine Display

4.Samples

5.Technical Parameter

Model | Install power(kw) | Actuall consumption(kw) | Capacity | Size(mm) |

DSE-65 production line | 80 | 56-64 | 100-150 kg/h | 32000*1500*3000 |

DSE-70 production line | 116 | 82-93 | 200-250 kg/h | 35000*1500*3000 |

DSE-75C production line | 154 | 108-123 | 300-400 kg/h | 35000*1500*3200 |

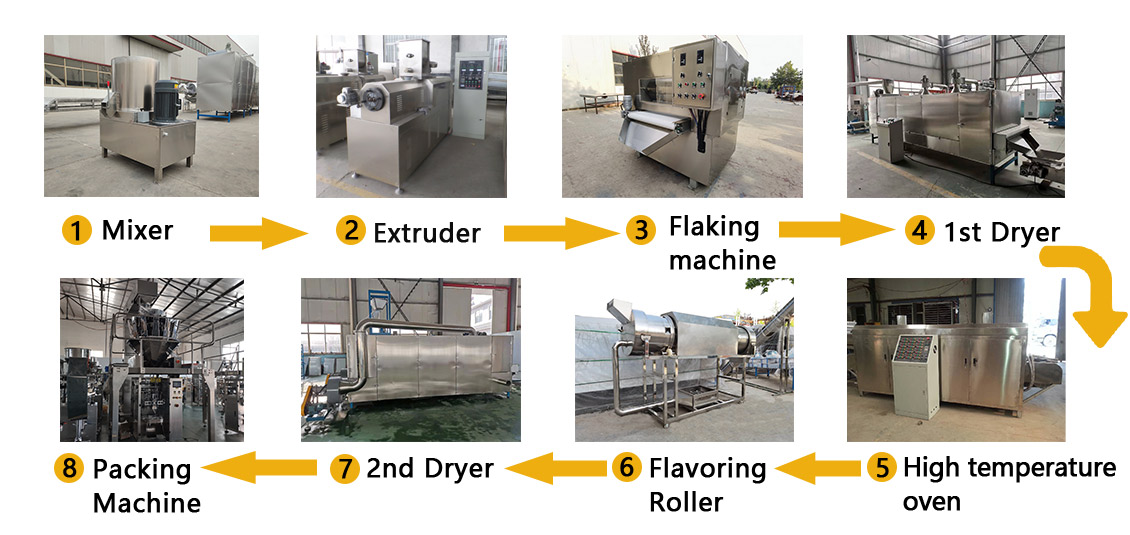

6.Flow Chart

Mixer→Screw conveyor→Extruder→Air conveyor→Flacking machine→Air conveyor→Dryer→Hoist→Sifter→High temperature dryer→Hoist→Flavoring roller→Hoist→Dryer→Cooling conveyor→Hoist→Packing machine

7.Product Advantages

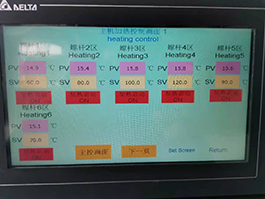

1.Using high-performance press rollers and advanced technology, non-sticky materials, stable output, uniform product thickness.High tempereature oven to bake the flakes more crunchy.

2.Reasonable configuration, convenient operation and simple maintenance,International famous parts and electric components,promise machine quality.

3.Corn flakesl and breakfast cereals of different shapes can be produced by changing molds,All food and material contact parts are made of 304 stainless steel to ensure product quality.

4.Oven energy can be selected from electricity, oil, gas according to local energy pricesNewly designed seasoning process, can spray syrup, with heating, will not solidify.

5.High degree of automation, the entire production line only needs 1-2 people to operate,3dryer process guarantee product taste and quality.

Send your message to us

Related News

Decrypt the Large Twin Screw Extruder

2024-12-20

What We Should to Know When Choose Pet Food

2024-12-11

Submitted successfully

We will contact you as soon as possible

Close