Dog Food Extruder Machine

Lead Time: 15-25 days

Materials: carbon steel

Voltage: Customized, 110v-440v,50-60hz.

Core Components Brand: Siemens,Delta, Schneider, Baltur

Shipping: Support to sea freight, land and air freight

Service:

1 One year warranty, lifetime service

2 Local engineer on-site service available within 14 working days

Product Details

1.Introduction

Mainly used in the production and processing of various floating and sinking aquatic feeds, especially suitable for the production of various floating aquatic feeds, and also widely used in the production and processing of pet food.

2.Production Video

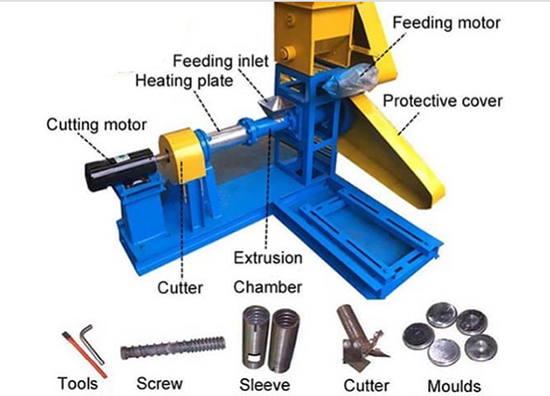

3.Machine display

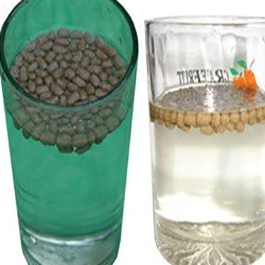

4.Samples

5.Technical parameter

Model | Capacity/output | Main Motor | Feeder Motor | Screw Diameter | Cutter Motor | Dimension |

BRT40 | 40-50kg/h | 5.5kw (220V) | 0.4kw | Φ40 | 0.4kw | 1.36*1.60*0.85m |

BRT60 | 100-150kg/h | 15kw | 0.4kw | Φ60 | 0.4kw | 1.36*1.67*0.85m |

BRT70 | 180-250kg/h | 18.5kw | 0.4kw | Φ70 | 0.4kw | 1.36*1.67*0.85m |

BRT80 | 250-300kg/h | 22kw | 1.5kw | Φ80 | 0.75kw | 1.36*1.95*0.84m |

BRT90 | 300-400kg/h | 30kw | 1.5kw | Φ90 | 1.5kw | 1.8*2.6*1.15m |

BRT100 | 400-500kg/h | 30kw | 1.5kw | Φ100 | 1.5kw | 1.8*2.6*1.15m |

BRT120 | 600-700kg/h | 55kw | 1.5kw | Φ120 | 2.2kw | 2.2*2.8*1.2m |

BRT135 | 750-800kg/h | 75kw | 1.5kw | Φ135 | 2.2kw | 2.2*2.8*1.2m |

BRT160 | 1000-1200kg/h | 90kw | 1.5kw | Φ160 | 2.2kw | 2.3*3.0*1.2m |

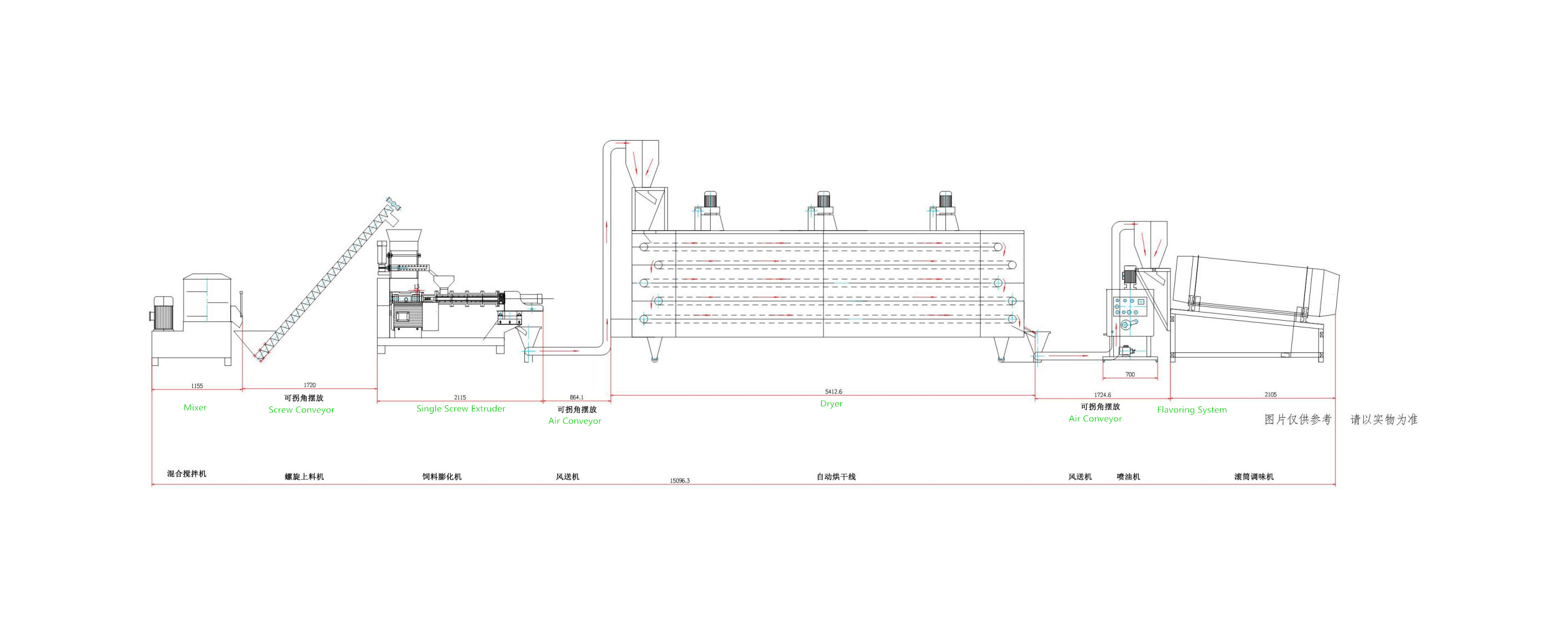

6.Flow chart

Mixer→Screw Conveyor→Single Screw Extruder→Air Conveyor→Dryer→Air Conveyor→Flavoring System

7.Product advantages

•Maturation: The material is fully matured in about 10 seconds, and the puffing temperature varies depending on the raw material, generally ranging from 120°C to 175°C. Maturation can destroy growth inhibitors in a very short period of time and complete the processing under anaerobic conditions, which helps to preserve the content of protein, energy and vitamins, and can also reduce the browning of the product due to oxidation; it can improve the digestibility and palatability of the product.

• Puffing and molding: The raw material is suddenly reduced in pressure after continuous high pressure, which can cause the gelatinization of starch cells and the rupture of oil cells, and can be processed into the required product status;

• Dehydration: When the extruded material leaves the feed pellet extruder, due to the high temperature and high pressure in the cavity, the internal moisture immediately evaporates (flash), which is very beneficial for storage;

• Enhanced stability: The high temperature and high pressure in the puffing cavity can passivate the enzymes that cause spoilage in the material, avoiding the rapid destruction of nutrients in the material in the short term, and can enhance the stability of the product storage process;

Significant benefits: Studies by domestic and foreign breeding experts have shown that compared with pelleted feed, the feed-to-meat ratio can be reduced by 8-10%, which will reduce feeding costs, shorten fattening time, and improve economic benefits.

Send your message to us

Related News

Decrypt the Large Twin Screw Extruder

2024-12-20

What We Should to Know When Choose Pet Food

2024-12-11

Submitted successfully

We will contact you as soon as possible

Close