Dog Food Products Extruder

With the improvement of society, the demand for all types of pet meals for dogs, cats and birds has extended dramatically and is shifting toward standardization and scale. According to the market demand, Bright has developed a new Big Pet Dog Food Products Extruder manufacturing line. Big Pet Dog Food Extruder manufacturing line has real looking design, excessive diploma of automation, steady overall performance and handy operation. Big Pet Dog Food Extruder merchandise are characterised by means of novel shape, special taste, wealthy vitamin and effortless digestion, which are nearer to the necessities of human food.

Lead Time: 15-25 days

Materials: stainless steel 304

Voltage: Customized, 110v-440v,50-60hz.

Core Components Brand: Siemens,Delta, Schneider, Baltur

Shipping: Support to sea freight, land and air freight

Service:

1 One year warranty, lifetime service

2 Local engineer on-site service available within 14 working days

Product Details

Dog Food Products Extruder

1.Introduction

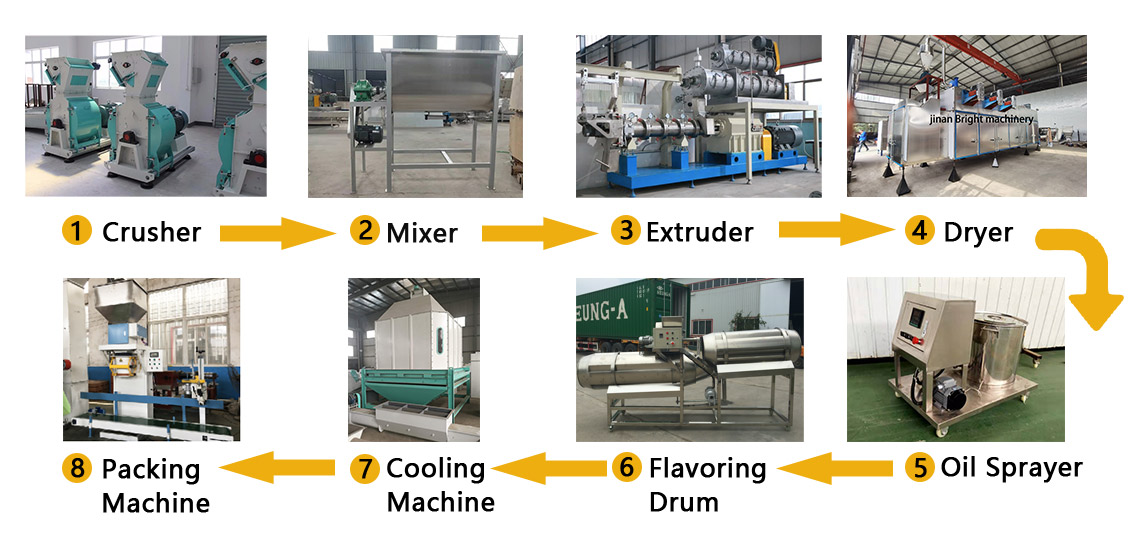

Dog Food Products Extruder ,The computerized massive workable canines ingredients manufacturing line makes powdered raw resources such as corn flour into canines foods through the manner of mixing,extruding,drying,flavoring and cooling. The equal manufacturing line can produce dogs foods of a range of shapes and sizes. At the equal time, the equal dogs foods can be matched with one of a variety laptop computer manufacturing traces in accordance to awesome capacity.

2.Production video

3.Machine display

4.Samples

5.Technical parameter

| Model | Install power(kw) | Actuall consumption(kw) | Capacity | Size(mm) |

DSE-65 production line | 80 | 56-64 | 100-150 kg/h | 21000*1500*3000 |

DSE-70 production line | 116 | 82-93 | 200-250 kg/h | 21000*1500*3000 |

DSE-75 production line | 154 | 108-123 | 300-350 kg/h | 25000*1500*3200 |

DSE-85 production line | 194 | 137-156 | 400-500 kg/h | 25000*1500*3200 |

DSE-85S production line | 121(Steam dryer) | 85-97 | 600-800 kg/h | 28000*1500*3500 |

DSE-95S production line | 165(Steam dryer) | 115-132 | 1000-1800 kg/h | 28000*1500*3500 |

DSE-95S-2 production line | 295(Steam dryer) | 206-236 | 2000-3000 kg/h | 25000*20000*6000 |

DSE-95S-3 production line | 375(Steam dryer) | 263-300 | 3000-4000 kg/h | 25000*20000*13000 |

DSE-95S-4 production line | 496(Steam dryer) | 347-397 | 4000-5000 kg/h | 30000*25000*16000 |

DSE-130S production line | 540(Steam dryer) | 380-432 | 5000-6000 kg/h | 30000*30000*16000 |

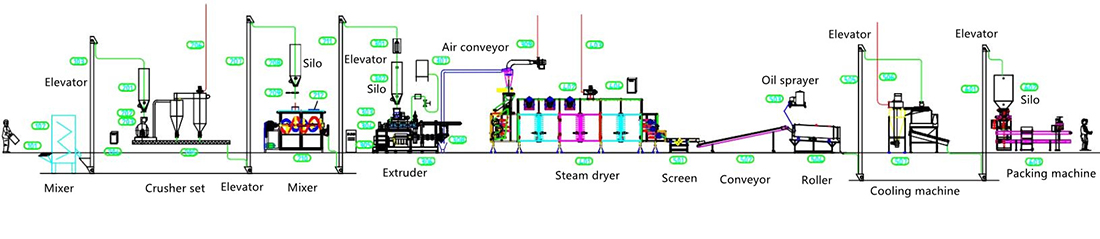

6.Flow chart

Mixer→Bucket Elevator→Extruder→Air Conveyor→Dryer→Hoister→Flavoring System→Cooling Conveyor→Air Conveyor→Packing Machine

7.Product advantages

1.Dog Food Products Extruder ,Customers can pick a fully automatic batching system, e,which is specifically computerized and saves manpower;central manipulate system;The range of silos can moreover be adjusted in accordance to the customer's formula, the features of the raw components and distinct factors to gain the excellent viable utilization rate and efficaciously manipulate the manufacturing cost;The silo is configured in the the front of the most necessary equipment to make sure continuous production.

2.Dog Food Products Extruder After raw cloth feeding the complete machine is automatic,mixing,crushing,extruding,drying,cooling and packing,continuous manufacturing line,reduce information work.only labor is required in feeding and packaging, and it can be designed as a multi-layer structure to reduce the ground space, and at the same time use gravity to transport efficaciously and save manufacturing costs.

3.Dog Food Products Extruder Using steam circulation oven, double door design,higher drying efficiency, saving strength consumption, saving manufacturing cost;stainless metallic Mesh or chain plate,promise product quality;Steam circulation system, geared up with circulating fan and dehumidification fan, superb immoderate drying efficiency.

4.Dog Food Products Extruder ,Engineers can provide pc design flowcharts and structure drawings in accordance to the acceptable situation of the customer's factory, CAD production, and 3D drawings to make positive handy set up and use with the useful resource of customers.

5.Dog Food Products Extruder adopts high-end configuration. Siemens motors, Delta inverters, Schneider electric powered powered devices. Adopt high-torque discipline body, immoderate strength and appropriate stability; use NSK gear, geared up with compelled lubrication, which consists of filter and condenser, with lengthy company life; pc barrel is made of 45# alloy steel, with wear-resistant bushing inside, use Long provider life, low replacement cost, steam heating, immoderate thermal efficiency; cantilever type rotary cutting, on hand to adjust, shortly device setting; full mixture screw, cloth w6mo5cr4v2, high-speed alloy steel, vacuum quenching, good sized applicability, can be blended in accordance to customer machine changes; Using a multi-shaft conditioner to precook the material to expand the protein content material cloth of the product and the output of the machine.

Send your message to us

Related News

Decrypt the Large Twin Screw Extruder

2024-12-20

What We Should to Know When Choose Pet Food

2024-12-11

Submitted successfully

We will contact you as soon as possible

Close