Pet Food Production Line Machine

Pet Food Production Line Machine,As a substances processing technology, puffing technological statistics used to be commenced in 1910. Its software program software in pet elements used to be as quickly as in the United States in the 1950s. The United States began out out to use the extrusion precept to produce pet food, that is, the screw and screw sleeve in the puffer had been used to extrude uncooked sources to make them warmness and pressurized, and the elements with excessive temperature and stress used to be extruded out of the mildew to recognize speedy extent growth due to shocking decompression.

Lead Time: 15-25 days

Materials: stainless steel 304

Voltage: Customized, 110v-440v,50-60hz.

Core Components Brand:Siemens,Delta, Schneider, Baltur

Shipping: Support to sea freight, land and air freight

Service:

1 One year warranty, lifetime service

2 Local engineer on-site service available within 14 working days

Product Details

Pet Food Production Line Machine

1 Introduction

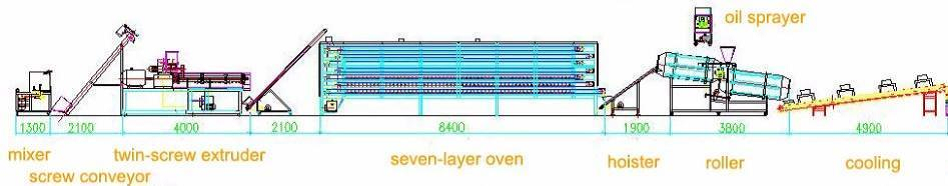

Pet Food Production Line Machine,The computerized doggies components manufacturing line makes powdered uncooked substances which consists of corn flour into puppies ingredients with the beneficial useful resource of the approach of blending,extruding,drying,flavoring and cooling. the equal manufacturing line can produce canines components of a vary of sizes and styles. on the equal time, the equal puppies components would per chance moreover be matched with amazing computing device manufacturing strains in accordance to one-of-a-kind potential.

2 Production Vide

3 Machine Display

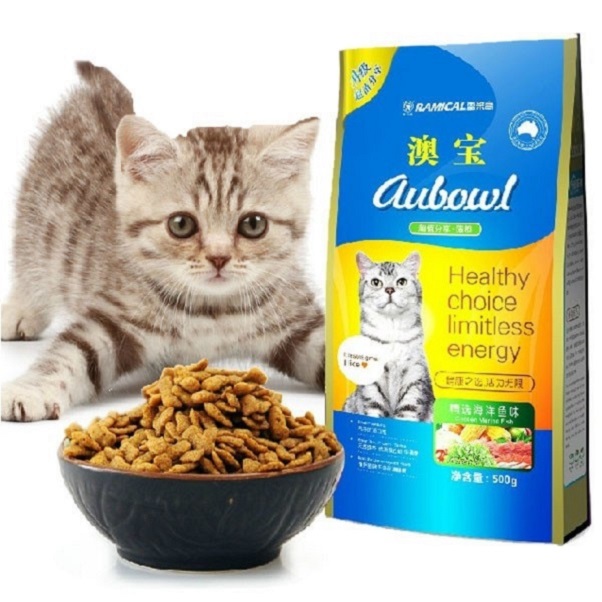

4 Samples

5 Technical Parameter

| Model | Install power(kw) | Actuall consumption(kw) | Capacity | Size(mm) |

DSE-65 production line | 80 | 56-64 | 100-150 kg/h | 21000*1500*3000 |

DSE-70 production line | 116 | 82-93 | 200-250 kg/h | 21000*1500*3000 |

DSE-75 production line | 154 | 108-123 | 300-350 kg/h | 25000*1500*3200 |

DSE-85 production line | 194 | 137-156 | 400-500 kg/h | 25000*1500*3200 |

DSE-85S production line | 121(Steam dryer) | 85-97 | 600-800 kg/h | 28000*1500*3500 |

DSE-95S production line | 165(Steam dryer) | 115-132 | 1000-1800 kg/h | 28000*1500*3500 |

DSE-95S-2 production line | 295(Steam dryer) | 206-236 | 2000-3000 Kg/h | 25000*20000*6000 |

DSE-95S-3 production line | 375(Steam dryer) | 263-300 | 3000-4000 Kg/h | 25000*20000*13000 |

DSE-95S-4 production line | 496(Steam dryer) | 347-397 | 4000-5000 Kg/h | 30000*25000*16000 |

DSE-130S production line | 540(Steam dryer) | 380-432 | 5000-6000 Kg/h | 30000*30000*16000 |

6 Flow Chart

Mixer→Screw Conveyor→Extruder→Air Conveyor→Dryer→Hoister→Flavoring System→Cooling Conveyor

7 Product Advantage

1.Pet Food Production Line Machine,The most quintessential producer for laptop computer pc computer is siemens motor, delta inverter, schneider or omron electrical elements so on. reliable every day performance, safety and durability, prolonged company life, reachable to update, appreciably ward off the utilization of the price.

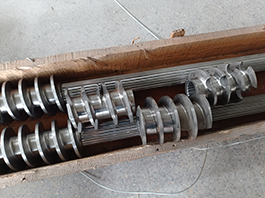

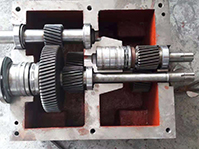

2.Pet Food Production Line Machine screw fabric is high-speed alloy steel, carburized, with hardness as hundreds as hrc fifty five-sixty five, immoderate put on resistance, excessive hardness, perfect toughness, non-obligatory 38crmoal, 12crmov, w6mo5cr4v2 material, prolonged employer lifestyles. some fashions are geared up with a combination screw, which has wider applicability of raw substances. the screw aggregate strategy can in addition be adjusted in protecting with one-of-a-kind merchandise, and one computer can in addition be used for increased than one functions.

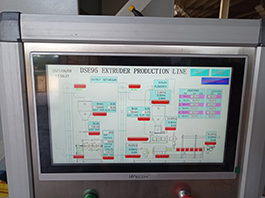

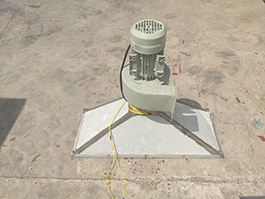

3.Pet Food Production Line Machine,The precept motor, rotary reducing motor and feeding motor are all managed with the aid of capacity of the use of workable of the utilization of frequency conversion, that can apprehend on hand start and effectually protect the motor, and would perchance in addition alter the tempo in defending with the product focal point to furnish elevated magnificent products; geared up with p.c contact exhibit off exhibit manipulate system, computing device temperature and the tempo adjustment is higher digital and the manipulate is huge precise.

4.Pet Food Production Line Machine use of a new kind of box, the container material qt400, real balance. equipment cloth 20crnimoa, carburizing and quenching, hardness hrc58-62, excessive precision, low noise, prolonged enterprise corporation existence; the use of jap nsk, skf bearings, immoderate precision, prolonged existence, everyday performance; oil pump motor, compelled indoors waft into lubrication; condenser, avert the ground temperature of gears and bearings will make large the issuer lifestyles; the filter out cleans the impurities internal the oil, improves the lubrication have an have an have an effect on on on and prolongs the corporation existence.

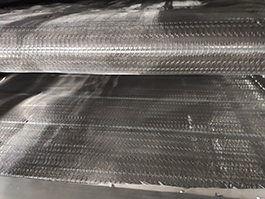

5.Pet Food Production Line Machine,Consistent with the authentic scenario, pinnacle notch electrical power assets, electricity, gasoline oil, gasoline, steam can be used to preserve manufacturing prices; geared up with circulating followers and dehumidification fanatics to promote warmness movement, dispose of water vapor, and beautify drying performance; 304 stainless metal mesh cloth and mesh are used. belt to make fine product first-class; adjustable taking walks speed, alter drying time in line with one-of-a-kind products, excessive performance.

Send your message to us

Related News

Decrypt the Large Twin Screw Extruder

2024-12-20

What We Should to Know When Choose Pet Food

2024-12-11

Submitted successfully

We will contact you as soon as possible

Close