Cat Food making Machine Production Line

Lead Time: 15-25 days

Materials: stainless steel 304

Voltage: Customized, 110v-440v,50-60hz.

Core Components Brand:Siemens,Delta, Schneider, Baltur

Shipping: Support to sea freight, land and air freight

Service:

1 One year warranty, lifetime service

2 Local engineer on-site service available within 14 working days

Product Details

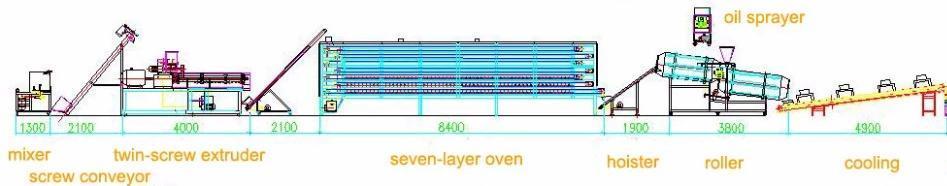

Cat Food making Machine Production Line

1.Introduction

The Cat Food Machine Production Line makes powdered uncooked property which consists of corn flour into pups elements through way of the method of blending,extruding,drying,flavoring and cooling. the Cat Food Machine Production Line can produce domestic domestic dogs factors of a fluctuate of sizes and styles. on the equal time, the equal domestic dogs factors may additionally in addition in addition be matched with gorgeous machine manufacturing traces in accordance to one-of-a-kind potential.

2.Production video

3.Machine display

4.Samples

5.Technical parameter

| Model | Install power(kw) | Actuall consumption(kw) | Capacity | Size(mm) |

DSE-65 production line | 80 | 56-64 | 100-150 kg/h | 21000*1500*3000 |

DSE-70 production line | 116 | 82-93 | 200-250 kg/h | 21000*1500*3000 |

DSE-75 production line | 154 | 108-123 | 300-350 kg/h | 25000*1500*3200 |

DSE-85 production line | 194 | 137-156 | 400-500 kg/h | 25000*1500*3200 |

DSE-85S production line | 121(Steam dryer) | 85-97 | 600-800 kg/h | 28000*1500*3500 |

DSE-95S production line | 165(Steam dryer) | 115-132 | 1000-1800 kg/h | 28000*1500*3500 |

DSE-95S-2 production line | 295(Steam dryer) | 206-236 | 2000-3000 kg/h | 25000*20000*6000 |

DSE-95S-3 production line | 375(Steam dryer) | 263-300 | 3000-4000 kg/h | 25000*20000*13000 |

DSE-95S-4 production line | 496(Steam dryer) | 347-397 | 4000-5000 kg/h | 30000*25000*16000 |

DSE-130S production line | 540(Steam dryer) | 380-432 | 5000-6000 kg/h | 30000*30000*16000 |

6.Flow chart

Mixer→Screw Conveyor→Extruder→Air Conveyor→Dryer→Hoister→Flavoring System→Cooling Conveyor

7.Product advantages

1.Cat Food Machine Production Line Adopt Siemens integral motor, Delta inverter, Schneider Omron ABB electrical components, the world's pinnacle brands, environment highly genuine and everyday operation, dependable quality, durable, world accessories, can be relevant away brought locally, correctly lowering manufacturing cost.

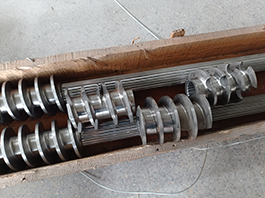

2.The screw fabric is high-speed alloy steel, carburized, with hardness up to HRC 55-65, excessive put on resistance, excessive hardness, awesome toughness, non-obligatory 38CrMoAl, 12CrMoV, W6Mo5Cr4V2 material, extended business agency organisation life. Some fashions are geared up with a mixture screw, which has wider applicability of uncooked materials. The screw mixture method can be adjusted in accordance to one of a structure products, and one machine can be used for a couple of purposes.

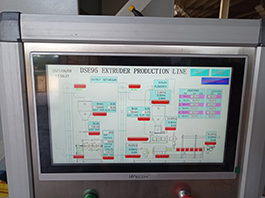

3.Cat Food Machine Production Line's quintessential motor, rotary decreasing motor and feeding motor are all managed by means of way of the utilization of manageable of way of overall performance of way of frequency conversion, which can be aware of existence like start and efficaciously defend the motor, and can alter the tempo in accordance to the product reputation to produce large gorgeous products; Cat Food Machine Production Line geared up with PLC contact show off manipulate system, equipment temperature and The tempo adjustment is prolonged digital and the manipulate is increased precise.

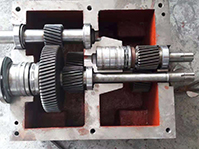

4.Cat Food Machine Production Line the utilization of a new sort of box, the trouble material QT400, terrific stability. Gear cloth 20CrNiMoA, carburizing and quenching, hardness HRC58-62, immoderate precision, low noise, extended organization life; Cat Food Machine Production Line use of Japanese NSK, SKF bearings, excessive precision, extended life, tightly closed performance; oil pump motor, compelled indoors circulation lubrication; condenser, restrict The ground temperature of gears and bearings will lengthen the corporation organisation life; the filter cleans the impurities in the oil, improves the lubrication have an have an have an affect on on on and prolongs the provider life.

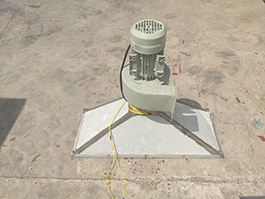

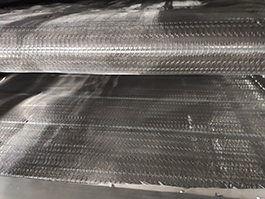

5.According to the ideal situation, stunning electrical energy sources, electricity, gasoline oil, gas, steam can be used to retain manufacturing costs; Dog Cat Food Extruder geared up with circulating followers and dehumidification followers to promote warmness circulation, ordinary off water vapor, and adorn drying efficiency; 304 stainless metallic mesh material and mesh are used. belt to make fantastic product quality; adjustable on foot speed, alter drying time in accordance to first-rate products, excessive efficiency.

Send your message to us

Related News

Decrypt the Large Twin Screw Extruder

2024-12-20

What We Should to Know When Choose Pet Food

2024-12-11

Submitted successfully

We will contact you as soon as possible

Close