Dry Food Machine For Dog

As a meals processing technology, puffing science was once commenced in 1910. Its utility in pet meals used to be in the United States in the 1950s. The United States commenced to use the extrusion precept to produce pet food, that is, the screw and screw sleeve in the puffer have been used to extrude uncooked substances to make them heat and pressurized, and the meals with excessive temperature and stress used to be extruded out of the mould to recognize speedy extent enlargement due to surprising decompression.

Lead Time: 15-25 days

Materials: stainless steel 304

Voltage: Customized, 110v-440v,50-60hz.

Core Components Brand:Siemens,Delta, Schneider, Baltur

Shipping: Support to sea freight, land and air freight

Service:

1 One year warranty, lifetime service

2 Local engineer on-site service available within 14 working days

Product Details

Dry Food Machine For Dog

1 Introduction

Dry Food Machine For Dog makes use of grain pellets or powders as raw elements and consists of many processes. Puffing is an vital hyperlink in the method of canine meals processing, and the enlargement method is additionally a procedure of canine meals uncooked fabric molding. During the molding process, water is introduced in the shape of steam to make the uncooked fabric starch in canine meals gelatinize, and the temperature rises to a hundred ℃~180 ℃. Because of the wonderful strain earlier than extrusion, the stress is launched without delay all through extrusion, so that the canine meals swiftly expands and foams, and the water evaporates, Therefore, the canine meals processed by means of the puffing procedure normally has excessive dietary price that is effortless to digest and absorb.

2 Production Video

<p

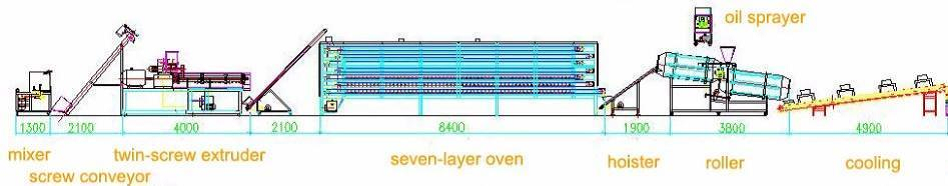

3 Machine Display

4 Samples

5 Technical Parameter

| Model | Install power(kw) | Actuall consumption(kw) | Capacity | Size(mm) |

DSE-65 production line | 80 | 56-64 | 100-150 kg/h | 21000*1500*3000 |

DSE-70 production line | 116 | 82-93 | 200-250 kg/h | 21000*1500*3000 |

DSE-75 production line | 154 | 108-123 | 300-350 kg/h | 25000*1500*3200 |

DSE-85 production line | 194 | 137-156 | 400-500 kg/h | 25000*1500*3200 |

DSE-85S production line | 121(Steam dryer) | 85-97 | 600-800 kg/h | 28000*1500*3500 |

DSE-95S production line | 165(Steam dryer) | 115-132 | 1000-1800 kg/h | 28000*1500*3500 |

DSE-95S-2 production line | 295(Steam dryer) | 206-236 | 2000-3000 Kg/h | 25000*20000*6000 |

DSE-95S-3 production line | 375(Steam dryer) | 263-300 | 3000-4000 Kg/h | 25000*20000*13000 |

DSE-95S-4 production line | 496(Steam dryer) | 347-397 | 4000-5000 Kg/h | 30000*25000*16000 |

DSE-130S production line | 540(Steam dryer) | 380-432 | 5000-6000 Kg/h | 30000*30000*16000 |

6 Flow Chart

Mixer→Screw Conveyor→Extruder→Air Conveyor→Dryer→Hoister→Flavoring System→Cooling Conveyor

7 Product Advantage

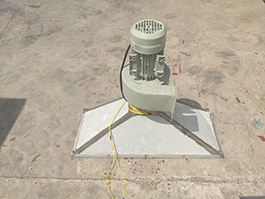

1.Dry Food Machine For Dog,The most necessary producer for laptop computer is siemens motor, delta inverter, schneider or omron electrical components so on. reliable daily performance, safety and durability, prolonged company life, accessible to update, considerably restriction the utilization of the price.

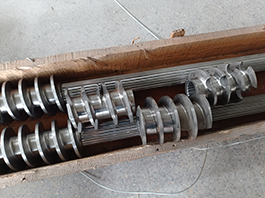

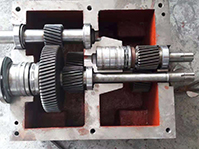

2.Dry Food Machine For Dog screw material is high-speed alloy steel, carburized, with hardness as thousands as hrc fifty five-sixty five, immoderate put on resistance, immoderate hardness, proper toughness, non-obligatory 38crmoal, 12crmov, w6mo5cr4v2 material, prolonged company lifestyles. some fashions are outfitted with a aggregate screw, which has wider applicability of raw substances. the screw aggregate strategy can moreover be adjusted in keeping with unique merchandise, and one laptop can moreover be used for larger than one functions.

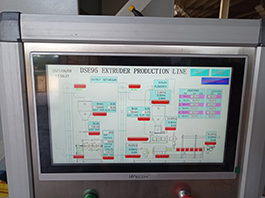

3.Dry Food Machine For Dog,The precept motor, rotary lowering motor and feeding motor are all managed through potential of the utilization of frequency conversion, that can apprehend handy begin and effectually defend the motor, and would possibly additionally alter the tempo in defending with the product consciousness to furnish extended superb products; prepared with p.c contact showcase exhibit manipulate system, gadget temperature and the tempo adjustment is increased digital and the manipulate is large precise.

4.Dry Food Machine For Dog,The use of a new kind of box, the container cloth qt400, actual balance. equipment material 20crnimoa, carburizing and quenching, hardness hrc58-62, excessive precision, low noise, prolonged issuer existence; the use of jap nsk, skf bearings, immoderate precision, prolonged existence, consistent performance; oil pump motor, compelled inner glide into lubrication; condenser, limit the floor temperature of gears and bearings will make bigger the company lifestyles; the filter out cleans the impurities internal the oil, improves the lubrication have an have an effect on on and prolongs the company existence.

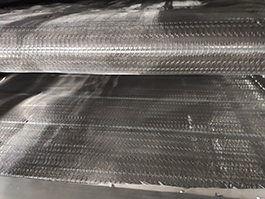

5.Dry Food Machine For Dog,Consistent with the real scenario, incredible power assets, electricity, gasoline oil, gasoline, steam can be used to preserve manufacturing prices; geared up with circulating followers and dehumidification fanatics to promote warmness movement, dispose of water vapor, and beautify drying performance; 304 stainless metallic mesh material and mesh are used. belt to make sure product first-class; adjustable walking speed, alter drying time in line with one-of-a-kind products, excessive performance.

Send your message to us

Related News

Decrypt the Large Twin Screw Extruder

2024-12-20

What We Should to Know When Choose Pet Food

2024-12-11

Submitted successfully

We will contact you as soon as possible

Close