Tortilla Chips Processing Machine

Tortilla Chips processing machine has the characteristics of "wide range of applicable raw materials, convenient operation and maintenance, low energy consumption, high output" and so on. Tortilla Chips processing machine puffed small food with crisp taste, easy to digest, unique flavor, easy to carry, is the ideal leisure fried snack food for consumers

Lead Time: 15-25 days

Materials: stainless steel 304

Voltage: Customized, 110v-440v,50-60hz.

Core Components Brand: Siemens,Delta, Schneider, Baltur

Shipping: Support to sea freight, land and air freight

Service:

1 One year warranty, lifetime service

2 Local engineer on-site service available within 14 working days

Product Details

Tortilla Chips Processing Machine

1.Introduction

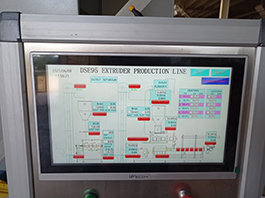

The Nachos/Doritos/Tortilla manufacturing line is made of corn flour after extrusion, molding and frying. Tortilla Chips Processing Machine predominant elements are corn meal, water, vegetable oil and salt. After frying, spray on the floor with a range of flavoring powder. Because of its crisp and delicious, it is cherished via youth and adults. The Tortilla Chips Processing Machine is outfitted with world-renowned electrical components and frequency converters, which are protected and dependable

2.Production Video

3.Machine Display

4.Samples

5.Technical Parameter

Model | Capacity/output | Installed Power | Power Consumption | Dimension |

DSE65 Doritos Snack Production Line | 100-150kg/h | 120kw | 96kw | 26*3*2.2m |

DSE65F Doritos Snack Production Line | 100-150kg/h | 124kw | 100kw | 26*3*2.2m |

DSE70 Doritos Snack Production Line | 200-250kg/h | 164kw | 132kw | 28*3*2.2m |

DSE70F Doritos Snack Production Line | 200-250kg/h | 130kw | 104kw | 26*3*2.2m |

DSE85 Doritos Snack Production Line | 300-500kg/h | 270kw | 216kw | 32*3*2.2m |

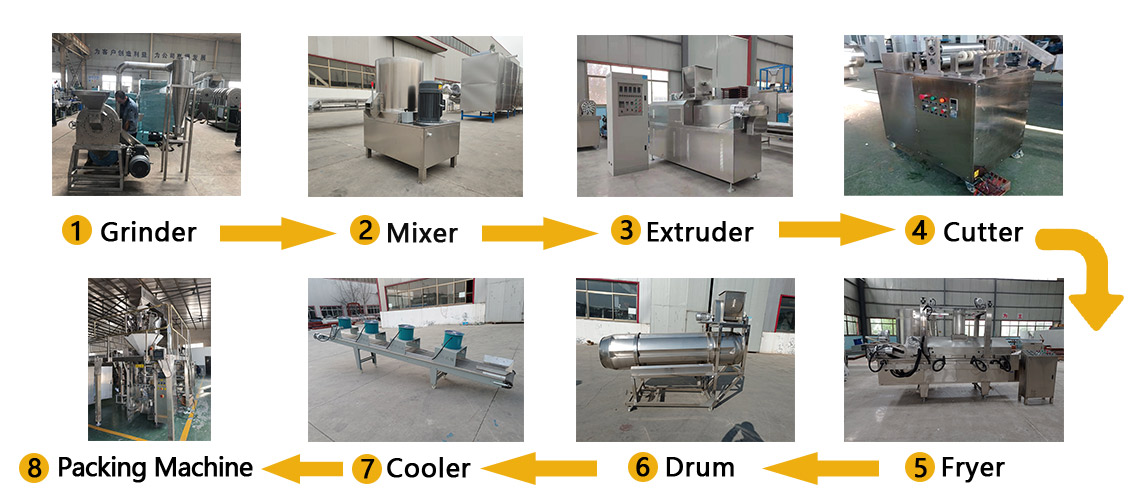

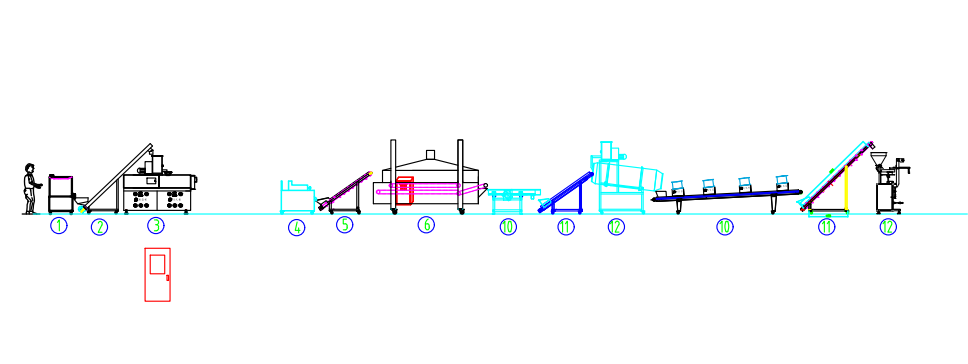

6.Flow Chart

Mixer→Screw Conveyor→Extruder→Cutter→Hoister→Fryer→Deoilling Machine→Hoister→Flavoring Drum→Cooling Conveyor→Hoister→Packing Machine

7.Product Advantages

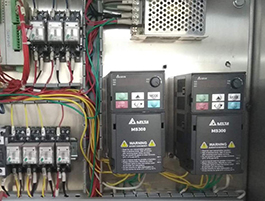

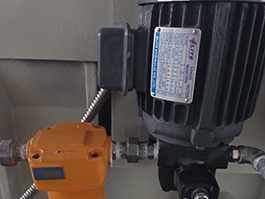

1 Adopt Siemens primary motor, Delta frequency manage converter, Schneider Omron ABB electrical components, the world's pinnacle brands, environment friendly and secure operation, dependable quality, durable, international accessories, can be immediately bought locally, efficiently decreasing manufacturing value

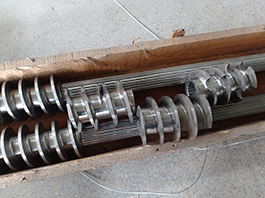

2. The Tortilla Chips Processing Machine screw fabric is high-speed alloy steel, carburized, with hardness up to HRC 55-65, excessive put on resistance, excessive hardness, top toughness, optionally available 38CrMoAl, 12CrMoV, W6Mo5Cr4V2 material, lengthy carrier life. Some Tortilla Chips Processing Machine fashions are outfitted with a mixture screw, which has wider applicability of uncooked materials. The Tortilla Chips Processing Machine screw aggregate approach can be adjusted in accordance to extraordinary products, and one laptop can be used for more than one purposes.

3 The important motor, rotary reducing motor and feeding motor of Tortilla Chips Processing Machine are all managed through frequency conversion, which can recognize tender begin and correctly shield the motor, and can alter the pace in accordance to the product repute to produce greater fine products; Tortilla Chips Processing Machine outfitted with PLC contact display screen manipulate system, gear temperature and The pace adjustment is greater digital and the manage is extra precise.

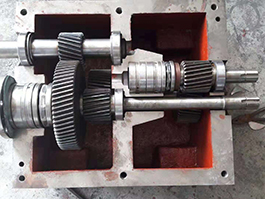

4 Using a new type of box, the box material QT400, good stability. Gear material 20CrNiMoA, carburizing and quenching, hardness HRC58-62, high precision, low noise, long service life; using Japanese NSK, SKF bearings, high precision, long life, stable performance; oil pump motor, forced internal circulation lubrication; condenser, lower The surface temperature of gears and bearings increases the service life; the filter cleans the impurities in the oil, improves the lubrication effect and prolongs the service life

5.The fried food Tortilla Chips Processing Machine is equipped with a fryer for curing, equipped with an oil filter system to keep the oil clean, ensure product quality and reduce production costs; it is equipped with an oil storage tank, automatic oil replenishment, and internal heating to ensure stable oil temperature and better finished product effect. ; Zone heating, adjustable heating temperature to meet the needs of different types of products for frying

Send your message to us

Related News

Decrypt the Large Twin Screw Extruder

2024-12-20

What We Should to Know When Choose Pet Food

2024-12-11

Submitted successfully

We will contact you as soon as possible

Close