Extruder Floating Fish Feed Machine For Big Capacity

Lead Time: 15-25 days

Materials: stainless steel 304

Voltage: Customized, 110v-440v,50-60hz.

Core Components Brand: Siemens,Delta, Schneider, Baltur

Shipping: Support to sea freight, land and air freight

Service:

1 One year warranty, lifetime service

2 Local engineer on-site service available within 14 working days

Product Details

Extruder Floating Fish Feed Machine For Big Capacity

1 Introduction

The types of fish feed have gone through a method from uncooked to cooked, from shallow processing to deep processing, from the unique fish and shrimp overwhelmed without delay to feeding, to the later matured pellet feeding, to the cutting-edge nutrient ratio scientific feeding. the extruded fish feed machinery and system production line specializes in the production of numerous types and specs of extruded aquatic fish feed for small and medium aquaculture farms and man or woman fisheries. the output of our fish feed system is one hundred kg in line with hour -10 lots per hour, divided into specific gadget configurations. high-protein extruded feed pellets, excessive protein content material, fish develop speedy, absorb properly, and the degree of feed waste is low, and fish excretion has less damage to water great, and may be recycled and used to increase ecological agriculture. it is a effective tool and manner for sustainable fishery development.

2 Production Video

3 Machine Display

4 Samples

5 Technical Parameter

Model | Install power(kw) | Actuall consumption(kw) | Capacity | Size(mm) |

DSE-65 production line | 80 | 56-64 | 100-150 kg/h | 21000*1500*3000 |

DSE-70 production line | 116 | 82-93 | 200-250 kg/h | 21000*1500*3000 |

DSE-75 production line | 154 | 108-123 | 300-350 kg/h | 25000*1500*3200 |

DSE-85 production line | 194 | 137-156 | 400-500 kg/h | 25000*1500*3200 |

DSE-95S productionline | 165(Steam dryer) | 115-132 | 1000-1800 kg/h | 28000*1500*3500 |

DSE-95S-2 production line | 295(Steam dryer) | 206-236 | 2000-3000 Kg/h | 25000*20000*6000 |

DSE-95S-3 production line | 375(Steam dryer) | 263-300 | 3000-4000 Kg/h | 25000*20000*13000 |

DSE-95S-4 production line | 496(Steam dryer) | 347-397 | 4000-5000 Kg/h | 30000*25000*16000 |

DSE-130S production line | 540(Steam dryer) | 380-432 | 5000-6000 Kg/h | 30000*30000*16000 |

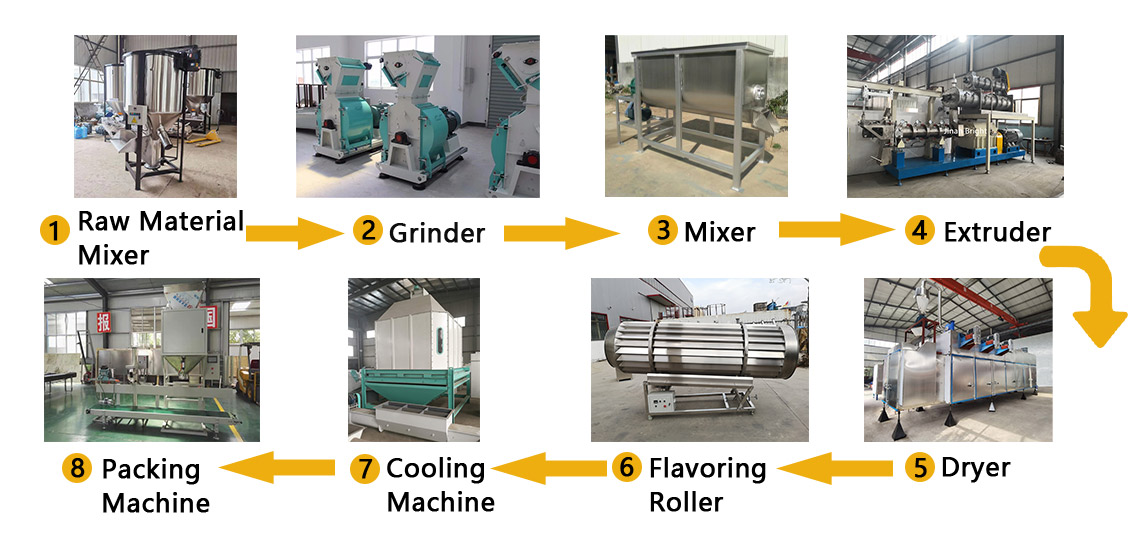

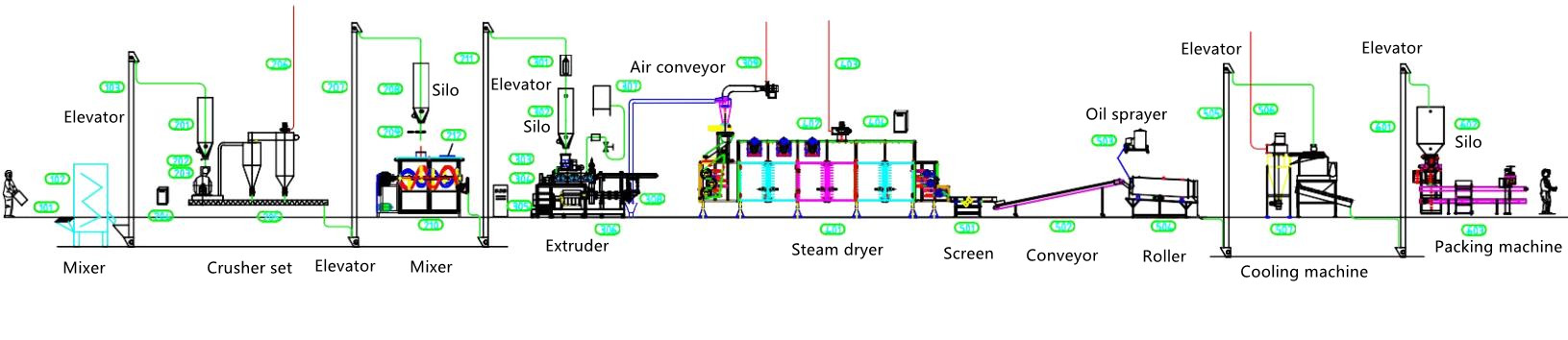

6 Flow Chart

Mixer→Bucket Elevator→Extruder→Air Conveyor→Dryer→Hoister→Flavoring System→Cooling Conveyor→Air Conveyor→Packing Machine

7 Product Advantages

1. Clients can choose a fully computerized batching gadget, e,that's noticeably automated and saves manpower;valuable control gadget;the wide variety of silos also can be adjusted in step with the customer's method, the traits of the raw substances and other elements to obtain the best utilization fee and effectively control the production cost;the silo is configured in front of the primary system to ensure non-stop production.

2.After raw material feeding the whole system is automatic,mixing,crushing,extruding,drying,cooling and packing,continuous production line,reduce manual work.only labor is required in feeding and packaging, and it can be designed as a multi-layer structure to reduce the floor space, and at the same time use gravity to transport efficiently and save production costs.

3.Using steam circulation oven, double door design,higher drying efficiency, saving energy consumption, saving production cost;stainless steel Mesh or chain plate,promise product quality;Steam circulation system, equipped with circulating fan and dehumidification fan, super high drying efficiency.

4. Engineers can provide machine layout flowcharts and layout drawings according to the actual situation of the customer's factory, CAD production, and 3D drawings to ensure smooth installation and use by customers.

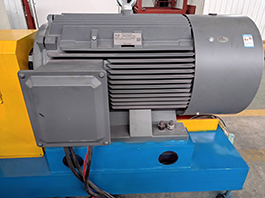

5.The extruder adopts high-end configuration. Siemens motors, Delta inverters, Schneider electric devices. Adopt high-torque box body, high strength and good stability; use NSK gear, equipped with forced lubrication, including filter and condenser, with long service life; machine barrel is made of 45# alloy steel, with wear-resistant bushing inside, use Long service life, low replacement cost, steam heating, high thermal efficiency; cantilever type rotary cutting, easy to adjust, fast tool setting; full combination screw, material w6mo5cr4v2, high-speed alloy steel, vacuum quenching, wide applicability, can be combined according to customer formula changes; Using a multi-shaft conditioner to precook the material to increase the protein content of the product and the output of the machine.

Send your message to us

Related News

Decrypt the Large Twin Screw Extruder

2024-12-20

What We Should to Know When Choose Pet Food

2024-12-11

Submitted successfully

We will contact you as soon as possible

Close