Fish Food Pellet Making Machine

Lead Time: 15-25 days

Materials: stainless steel 304

Voltage: Customized, 110v-440v,50-60hz.

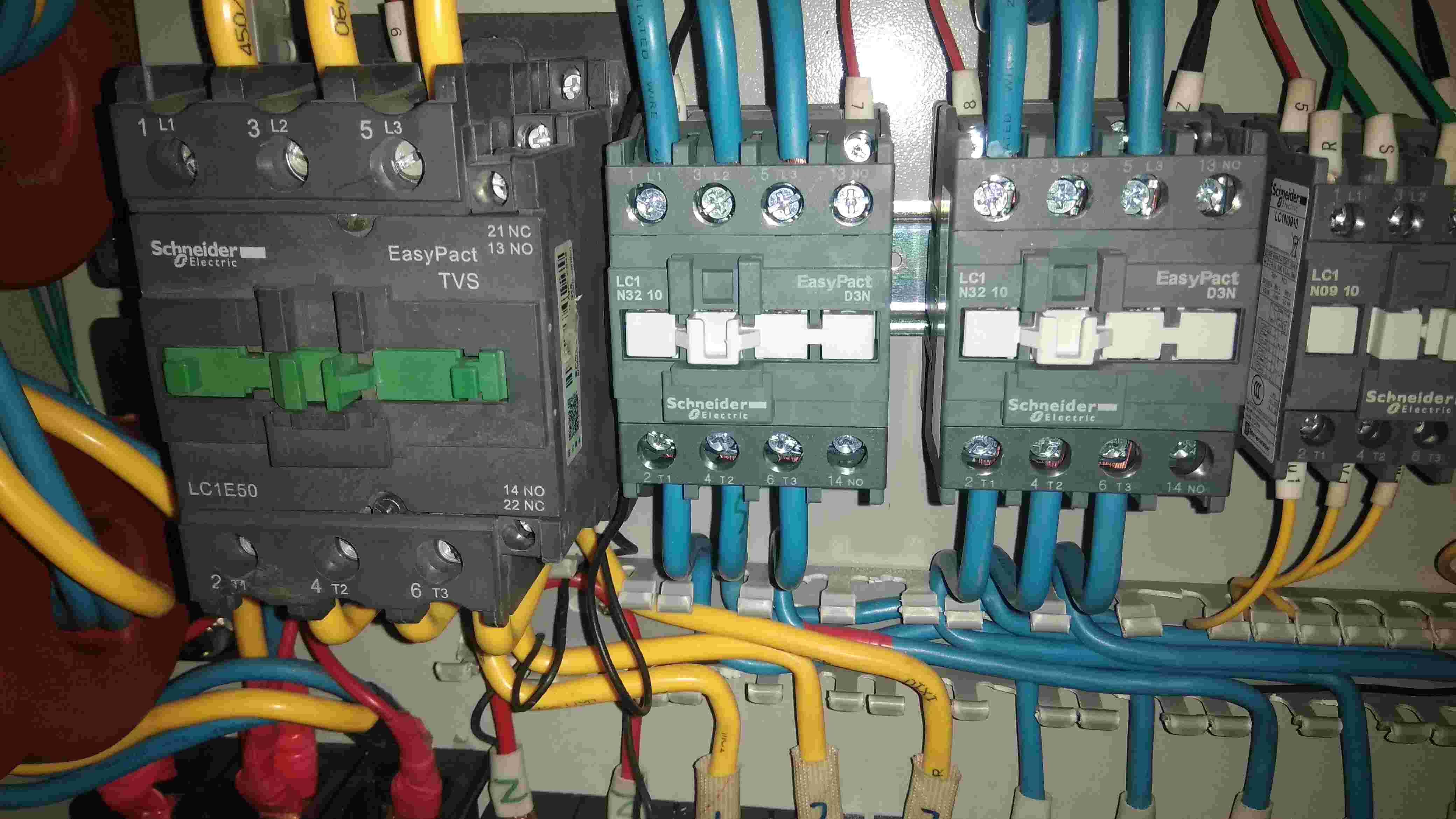

Core Components Brand: Siemens,Delta, Schneider, Baltur

Shipping: Support to sea freight, land and air freight

Service:

1 One year warranty, lifetime service

2 Local engineer on-site service available within 14 working days

Product Details

Fish Food Pellet Making Machine

1 Introduction

The kinds of fish feed have gone through a manner from uncooked to cooked, from shallow processing to deep processing, from the original fish and shrimp overwhelmed without delay to feeding, to the later matured pellet feeding, to the current nutrient ratio scientific feeding. the extruded fish feed equipment and device production line,specializes in the production of various types and specifications of extruded aquatic fish feed for small and medium aquaculture farms and character fisheries. the output of our fish feed device is a hundred kg according to hour -10 lots per hour, divided into special gadget configurations. high-protein extruded feed pellets, excessive protein content material, fish develop rapid, absorb well, and the degree of feed waste is low, and fish excretion has less harm to water high-quality, and can be recycled and used to expand ecological agriculture. it's miles a powerful tool and approach for sustainable fishery improvement.

2 Production Video

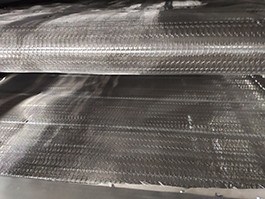

3 Machine Display

4 Sample

5 Technical Parameter

Model | Install power(kw) | Actuall consumption(kw) | Capacity | Size(mm) |

DSE-65 production line | 80 | 56-64 | 100-150 kg/h | 21000*1500*3000 |

DSE-70 production line | 116 | 82-93 | 200-250 kg/h | 21000*1500*3000 |

DSE-75 production line | 154 | 108-123 | 300-350 kg/h | 25000*1500*3200 |

DSE-85 production line | 194 | 137-156 | 400-500 kg/h | 25000*1500*3200 |

DSE-95S productionline | 165(Steam dryer) | 115-132 | 1000-1800 kg/h | 28000*1500*3500 |

DSE-95S-2 production line | 295(Steam dryer) | 206-236 | 2000-3000 Kg/h | 25000*20000*6000 |

DSE-95S-3 production line | 375(Steam dryer) | 263-300 | 3000-4000 Kg/h | 25000*20000*13000 |

DSE-95S-4 production line | 496(Steam dryer) | 347-397 | 4000-5000 Kg/h | 30000*25000*16000 |

DSE-130S production line | 540(Steam dryer) | 380-432 | 5000-6000 Kg/h | 30000*30000*16000 |

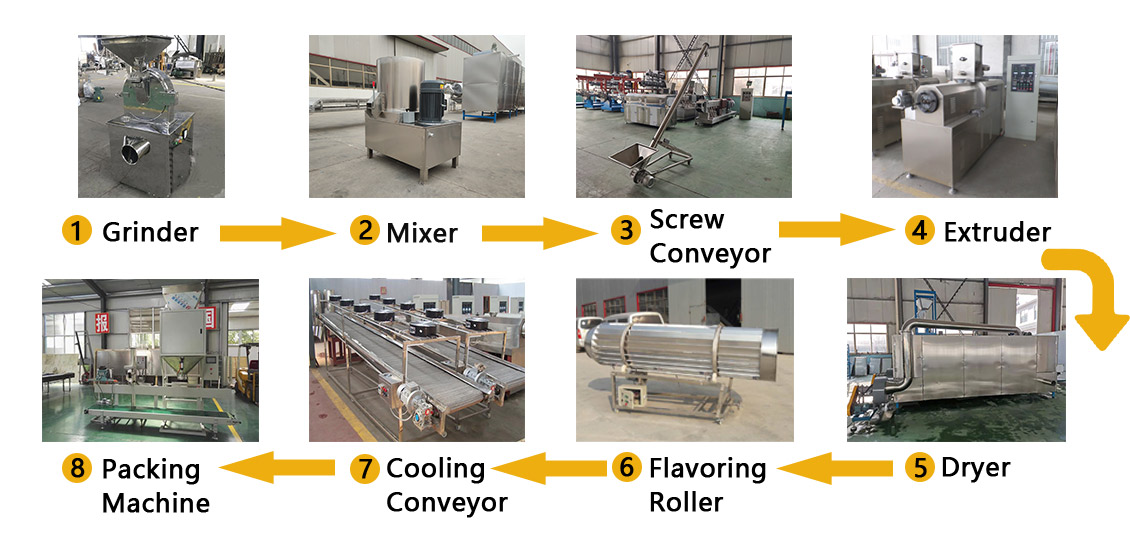

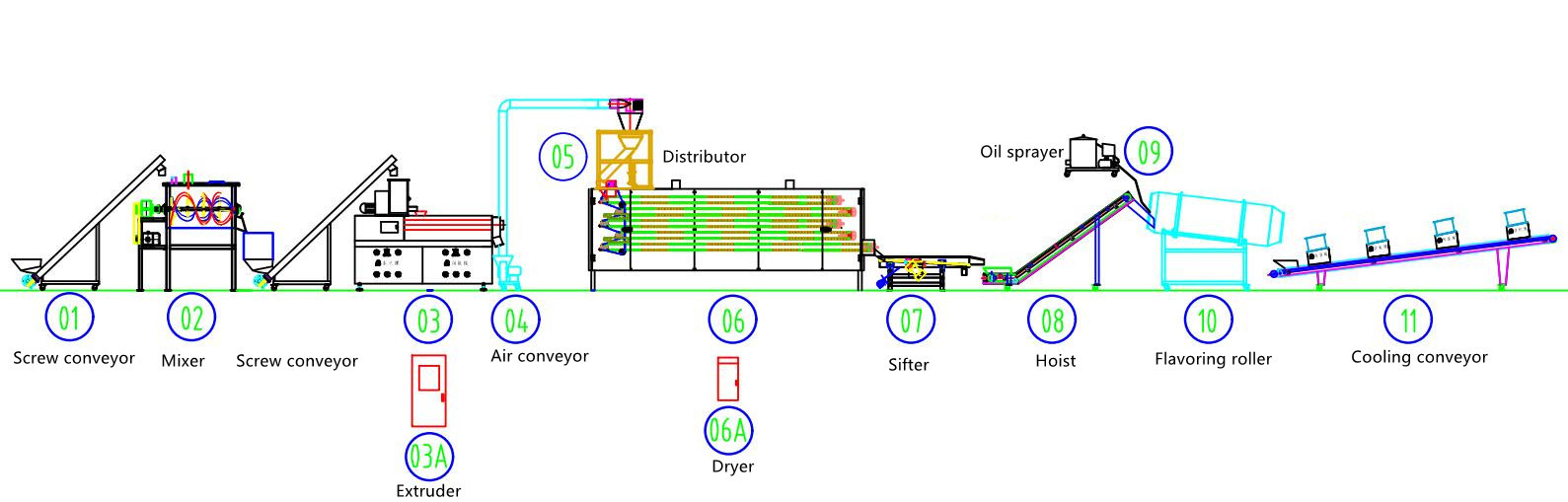

6 Flow Chart

Screw conveyor→Mixer→Screw conveyor→Extruder→Air conveyor→Dryer→Sifter→Hoist→Flavoring roller→Cooling conveyor

7 Product Advantage

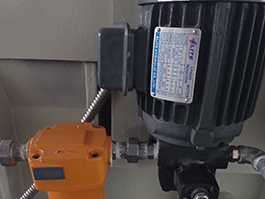

1.The gadget is geared up with siemens motor, delta inverter, schneider omron abb and other electric elements, the arena famous brand, secure and reliable, high efficiency, lengthy provider lifestyles, on the identical time can be purchased from everywhere in the global, handy replacement, reduce transportation costs.

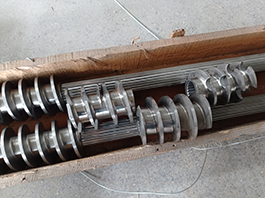

2.The screw material is high-velocity alloy steel, carburized, with hardness as much as hrc 55-65, excessive put on resistance, immoderate hardness, top durability, non-obligatory 38crmoal, 12crmov, w6mo5cr4v2 fabric, lengthy carrier lifestyles. a few models are equipped with a aggregate screw, which has wider applicability of raw materials. the screw mixture technique can be adjusted in keeping with different products, and one gadget may be used for a couple of functions.

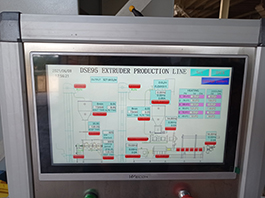

3.The number one motor, rotary slicing motor and feeding motor are all managed with the aid of way of frequency conversion, which could realise gentle begin and efficaciously shield the motor, and may regulate the fee in keeping with the product reputation to produce higher high-quality merchandise; equipped with p.c contact show manipulate tool, equipment temperature and the speed adjustment is extra digital and the manage is greater unique.

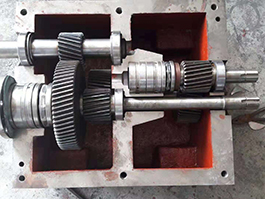

4.Using a cutting-edge sort of discipline, the field cloth qt400, appropriate balance. tools cloth 20crnimoa, carburizing and quenching, hardness hrc58-sixty two, excessive precision, low noise, prolonged carrier lifestyles; the use of eastern nsk, skf bearings, excessive precision, long existence, stable usual overall performance; oil pump motor, compelled internal circulate lubrication; condenser, decrease the ground temperature of gears and bearings will increase the carrier lifestyles; the clean out cleans the impurities inside the oil, improves the lubrication impact and prolongs the carrier existence.

5.Regular with the actual situation, distinct electricity sources, power, gasoline oil, gas, steam may be used to save production charges; ready with circulating fans and dehumidification fans to promote heat stream, do away with water vapor, and enhance drying performance; 304 stainless-steel mesh fabric and mesh are used. belt to make certain product extraordinary; adjustable walking tempo, modify drying time consistent with amazing products, excessive overall performance.

Send your message to us

Related News

Decrypt the Large Twin Screw Extruder

2024-12-20

What We Should to Know When Choose Pet Food

2024-12-11

Submitted successfully

We will contact you as soon as possible

Close