Artificial Rice Maker Machine

The synthetic rice made via the fortified rice processing line equipment twin-screw extruder is made of broken rice, which is floor via the pulverization method to grow to be best rice noodles. It is processed via sieving and different processes. The look is like rice. The synthetic rice made of yellow corn is mild yellow, and the white corn is white. They are all in a semi-puffed country and have a positive diploma of transparency. Rice made with corn dregs is delicious. At present, there are many kinds of synthetic rice on the market, such as sugar, lysine and vitamins, and it is a very handy food.

Lead Time: 15-25 days

Materials: stainless steel 304

Voltage: Customized, 110v-440v,50-60hz.

Core Components Brand: Siemens,Delta, Schneider, Baltur

Shipping: Support to sea freight, land and air freight

Service:

1 One year warranty, lifetime service

2 Local engineer on-site service available within 14 working days

Product Details

1.Introduction

Artificial Rice Maker Machine use of broken rice as raw material, and grinds broken rice with the aid of the pulverization approach to flip out to be pleasant rice noodles. The extruder of Artificial Rice Maker Machine adopts twin-screw configuration and is made of alloy fabric with the resource of unique process, so it has a prolonged provider life.Artificial Rice Maker Machine has a circulating water cooling device to make positive that the product is out of the mold. Artificial Rice Maker Machine adopts smart rotary reducing control, which is simple to operate, reachable and fast.

Artificial Rice Maker Machine is a meals manufacturing gear developed and produced thru the utilization of the agency in accordance to the present day ingredients meals layout needs. Artificial Rice Maker Machine adapts to the contemporary kingdom of affairs of people's dietary strengthening treatment in current society, meets people's necessities for dietary balance, and has the advantages of immoderate diploma of automation and strength saving. Artificial Rice Maker Machine can use larger than a few grains such as rice, millet, black rice, buckwheat, etc. as uncooked materials, add a range of vitamins, proteins and minerals for processing, squeeze, mature and structure in an extruder to regenerate new increased splendid weight loss application Rice, its ingesting technique is the equal as herbal rice and it is a great deal much less tricky and large convenient, each nutritious and healthy.

2.Production Video

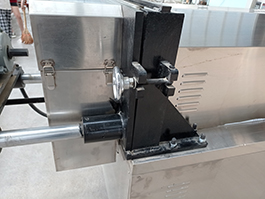

3.Machine Display

4.Samples

5 Technical Parameter

Model | Install power(kw) | Actuall consumption(kw) | Capacity | Size(mm) |

DSE-70 production line | 120 | 84-96 | 150-200 kg/h | 21000*1500*3000 |

DSE-75C production line | 150 | 105-120 | 250-300 kg/h | 24000*1500*3000 |

DSE-95C Production line | 490 | 342-392 | 400-500 kg/h | 32000*1500*3000 |

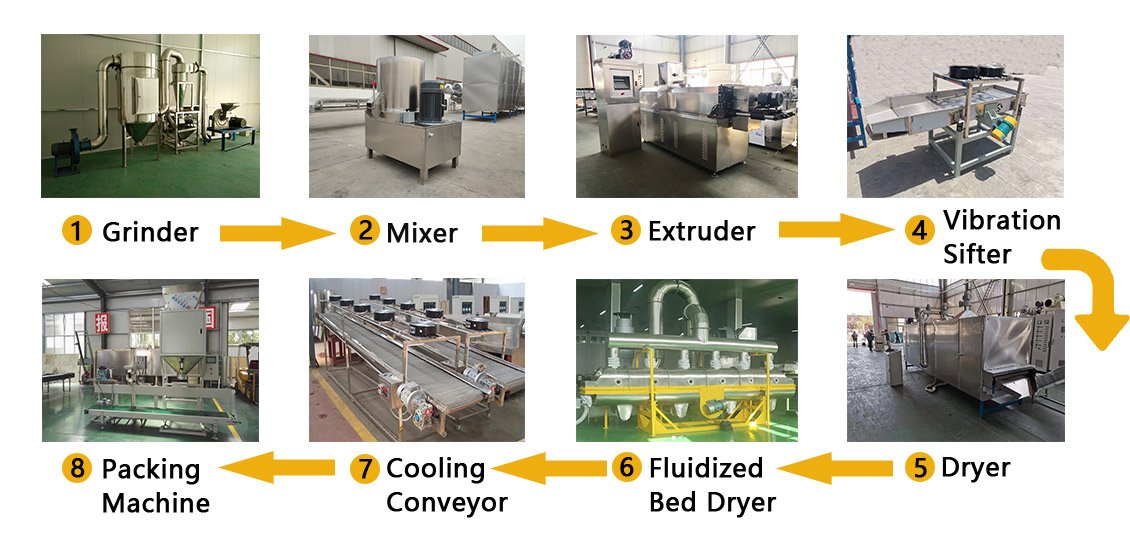

6.Flow Chart

Flow chart:Grider→Mixer→Screw conveyor→Extruder→Vibration cooling machine→Air conveyor→Dryer→Cooling conveyor

7.Product Advantages

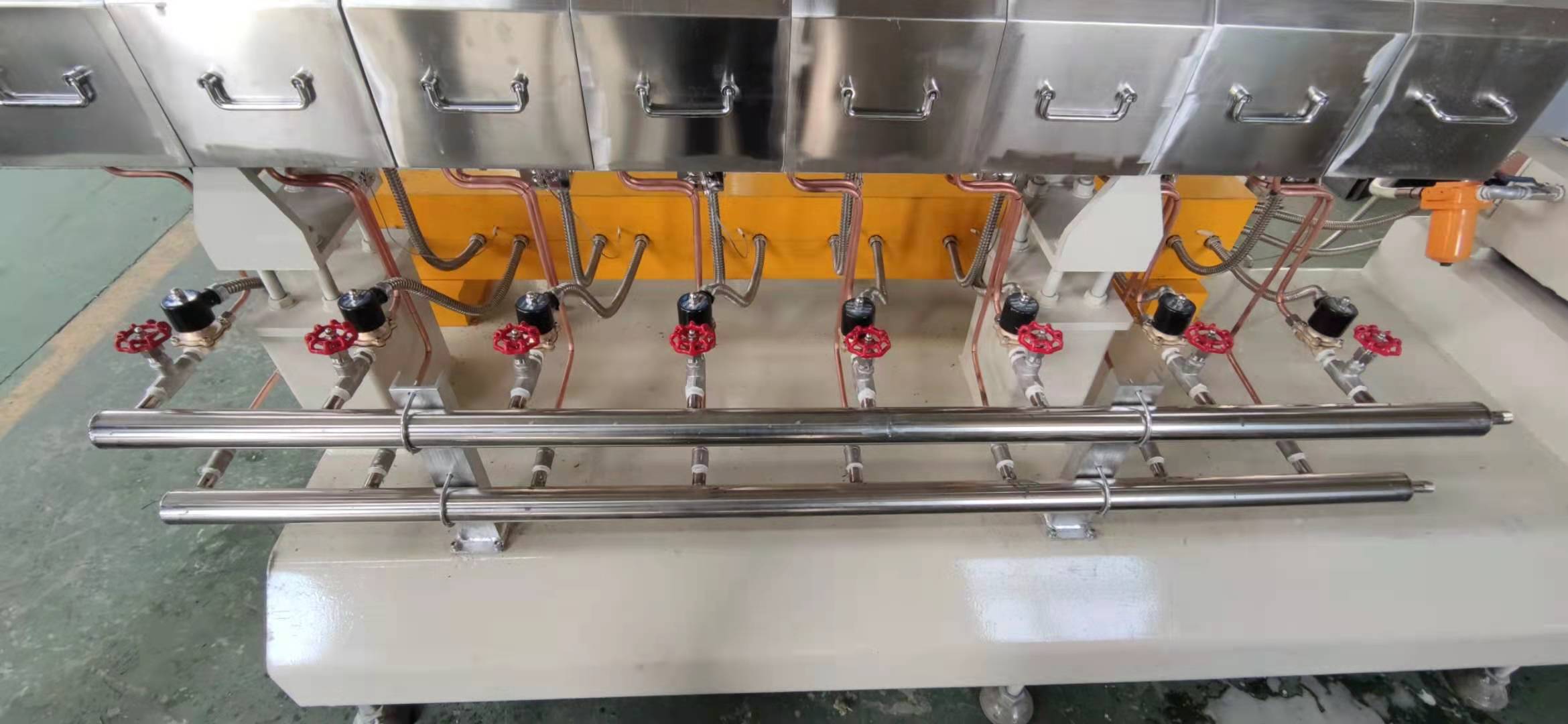

1. PLC contact display control, visible operation, easy operation, components and electrical components and different digital elements are adopted worldwide well-known brand, the fine of the desktop is guaranteed. Imported bearing group, sturdy bearing capacity, lengthy provider life.

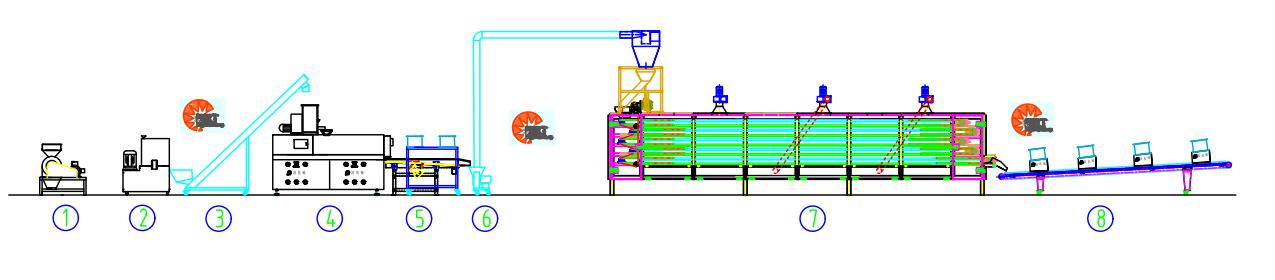

2. The barrel is geared up with a water injection system to higher meet the necessities of uncooked substances and quality,also can have a large vary of uncooked fabric adoption,Wider applicability of uncooked materials, can add a range of vitamins to produce dietary rice with exclusive functions.

3. Building block kind blended screw, can be mixed freely in accordance to specific uncooked substances and products,High-speed device metal material, hardness HRC≥62, lengthy carrier life,Unique rotary reducing plan to make certain product consistency and floor smoothness.

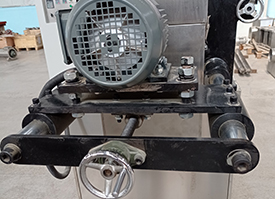

4. The dryer makes use of absolutely insulated box, adopts inner thermal circulation method, excessive thermal efficiency, low electricity consumption.The dryer has single-layer, three-layer, five-layer, and seven-layer ovens; a couple of buildings such as extended, reciprocating, etc.; more than one heating methods: electricity, steam, fuel/gas, reachable for selection, patron customization, pick the most appropriate machine.

Send your message to us

Related News

Decrypt the Large Twin Screw Extruder

2024-12-20

What We Should to Know When Choose Pet Food

2024-12-11

Submitted successfully

We will contact you as soon as possible

Close