Artificial Rice Process Line

Lead Time: 15-25 days

Materials: stainless steel 304

Voltage: Customized, 110v-440v,50-60hz.

Core Components Brand: Siemens,Delta, Schneider, Baltur

Shipping: Support to sea freight, land and air freight

Service:

1 One year warranty, lifetime service

2 Local engineer on-site service available within 14 working days

Product Details

1 Introduction

The utilization of Artificial Rice Process Line, the broken rice (broken rice and fallen rice embryo) can be restored, restored or processed into rice grains which may be almost the identical as ordinary entire rice, or in step with the requirements of scientific weight loss plan, some herbal nutrients alongside aspect numerous kinds miscellaneous grains are blended mutually in a certain share to make immoderate-nutrients rice and at as soon as rice with the equal cooking common overall performance and cooking approach (with taste) as normal rice.

The Artificial Rice Process Line is a meals manufacturing device advanced and produced with the beneficial aid of the corporation in maintaining with the cutting-edge-day foods vitamins desires. the manufacturing system adapts to the established scenario of people's dietary strengthening treatment in present day society, meets human beings's requirements for dietary balance, and has the advantages of immoderate diploma of automation and strength saving. the Artificial Rice Process Line can use a range of grains which consists of rice, millet, black rice, buckwheat, and many others. as raw materials, add severa nutrients, proteins and minerals for processing, squeeze, mature and form in an extruder to regenerate new greater terrific nutritional vitamins rice, its consuming technique is comparable to herbal rice and it is a long way an awful lot much less tough and larger handy, each nutritious and healthful.

2 Production Video

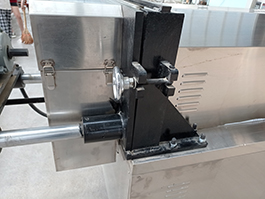

3 Machine Display

4 Samples

5 Technical Parameter

Model | Install power(kw) | Actuall consumption(kw) | Capacity | Size(mm) |

DSE-70 production line | 120 | 84-96 | 150-200 kg/h | 21000*1500*3000 |

DSE-75C production line | 150 | 105-120 | 250-300 kg/h | 24000*1500*3000 |

DSE-95C Production line | 490 | 342-392 | 400-500 kg/h | 32000*1500*3000 |

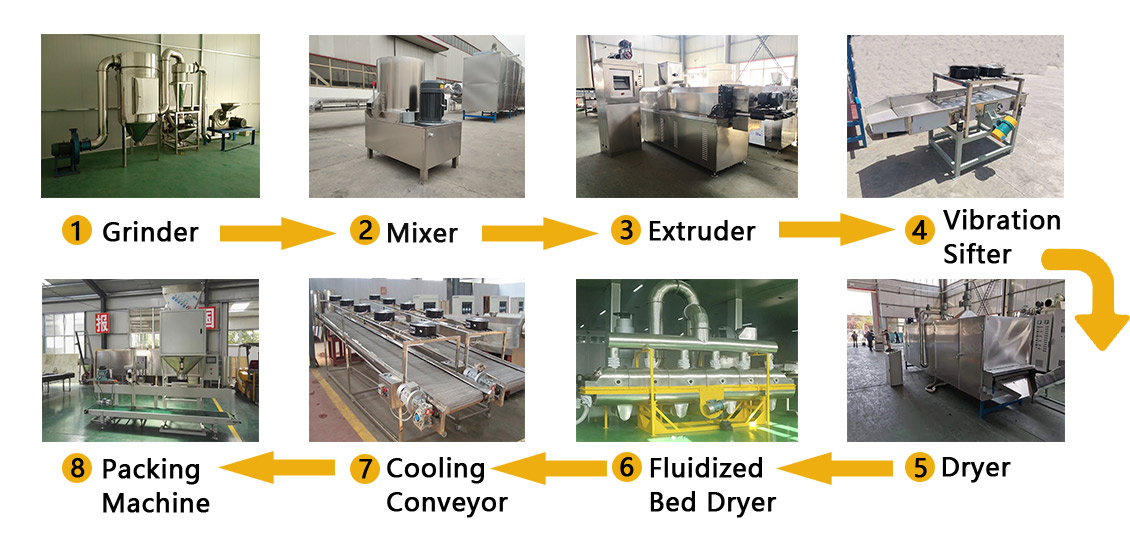

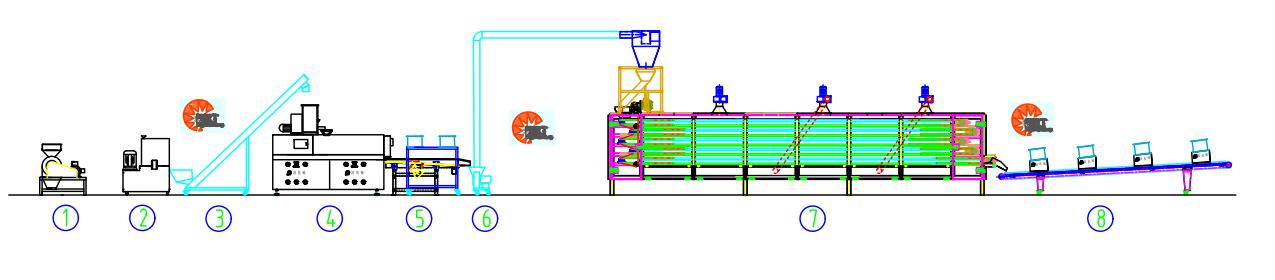

6 Flow Chart

Flow chart:Grider→Mixer→Screw conveyor→Extruder→Vibration cooling machine→Air conveyor→Dryer→Cooling conveyor

7 Product Advantages

1.Artificial Rice Process Line Percent contact display control, seen operation, easy operation, aspects and electric powered components and different electronic aspects are observed world well-known emblem, the nice of the desktop is assured. imported bearing institution, robust bearing capacity, lengthy carrier life.

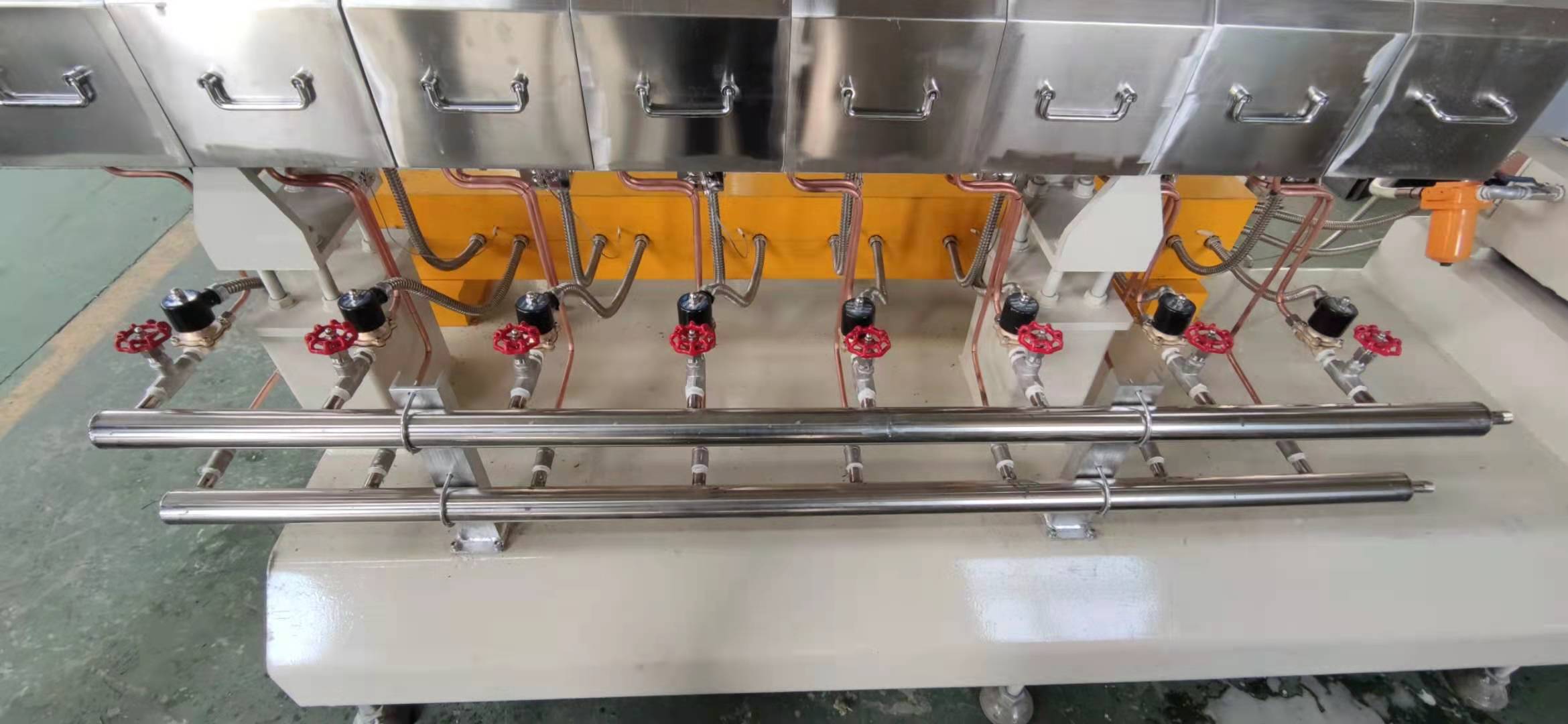

2.Artificial Rice Process Line barrel is outfitted with a water injection gadget to higher meet the necessities of uncooked substances and best,also can have a large vary of raw material adoption,wider applicability of uncooked substances, can add a choice of nutritional vitamins to grant dietary rice with great features.

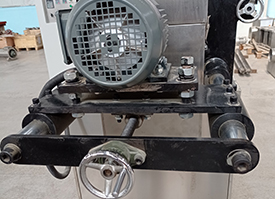

3.Building block kind combined screw, can be blended freely constant with great raw elements and products,excessive-pace gadget steel cloth, hardness hrc≥sixty two, lengthy issuer lifestyles,specific rotary reducing design to make sure product consistency and ground smoothness.

4.Artificial Rice Process Line dryer makes use of in reality insulated field, adopts interior thermal circulation technique, immoderate thermal performance, low power intake.the dryer has unmarried-layer, 3-layer, 5-layer, and seven-layer ovens; a couple of buildings along with extended, reciprocating, and so on.; more than one heating strategies: strength, steam, fuel/gas, to be had for selection, patron customization, choose the most appropriate device.

Send your message to us

Related News

Decrypt the Large Twin Screw Extruder

2024-12-20

What We Should to Know When Choose Pet Food

2024-12-11

Submitted successfully

We will contact you as soon as possible

Close