Artificial Rice Making Machinery

Lead Time: 15-25 days

Materials: stainless steel 304

Voltage: Customized, 110v-440v,50-60hz.

Core Components Brand: Siemens,Delta, Schneider, Baltur

Shipping: Support to sea freight, land and air freight

Service:

1 One year warranty, lifetime service

2 Local engineer on-site service available within 14 working days

Product Details

Artificial Rice Making Machinery

1 Introduction

The utilization of Artificial Rice Making Machinery, the damaged rice (broken rice and fallen rice embryo) can be restored, restored or processed into rice grains which might also be nearly the same as normal complete rice, or in step with the necessities of scientific weight loss plan, some natural vitamins alongside thing severa sorts miscellaneous grains are blended collectively in a positive share to make immoderate-nutrients rice and at as quickly as rice with the equal cooking frequent universal overall performance and cooking strategy (with taste) as everyday rice.

The Artificial Rice Making Machinery is a foods manufacturing machine superior and produced with the recommended resource of the organisation in preserving with the cutting-edge-day ingredients nutritional vitamins desires. the manufacturing device adapts to the installed situation of people's dietary strengthening remedy in existing day society, meets human beings's necessities for dietary balance, and has the benefits of excessive diploma of automation and energy saving. the Artificial Rice Making Machinery can use a vary of grains which consists of rice, millet, black rice, buckwheat, and many others. as uncooked materials, add severa nutrients, proteins and minerals for processing, squeeze, mature and shape in an extruder to regenerate new increased remarkable dietary nutritional vitamins rice, its ingesting method is related to natural rice and it is a lengthy way an lousy lot plenty much less hard and large handy, every nutritious and healthful.

2 Production Video

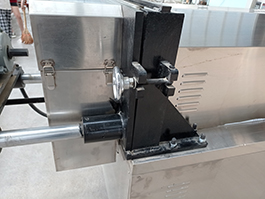

3 Machine Display

4 Samples

5 Technical Parameter

Model | Install power(kw) | Actuall consumption(kw) | Capacity | Size(mm) |

DSE-70 production line | 120 | 84-96 | 150-200 kg/h | 21000*1500*3000 |

DSE-75C production line | 150 | 105-120 | 250-300 kg/h | 24000*1500*3000 |

DSE-95C Production line | 490 | 342-392 | 400-500 kg/h | 32000*1500*3000 |

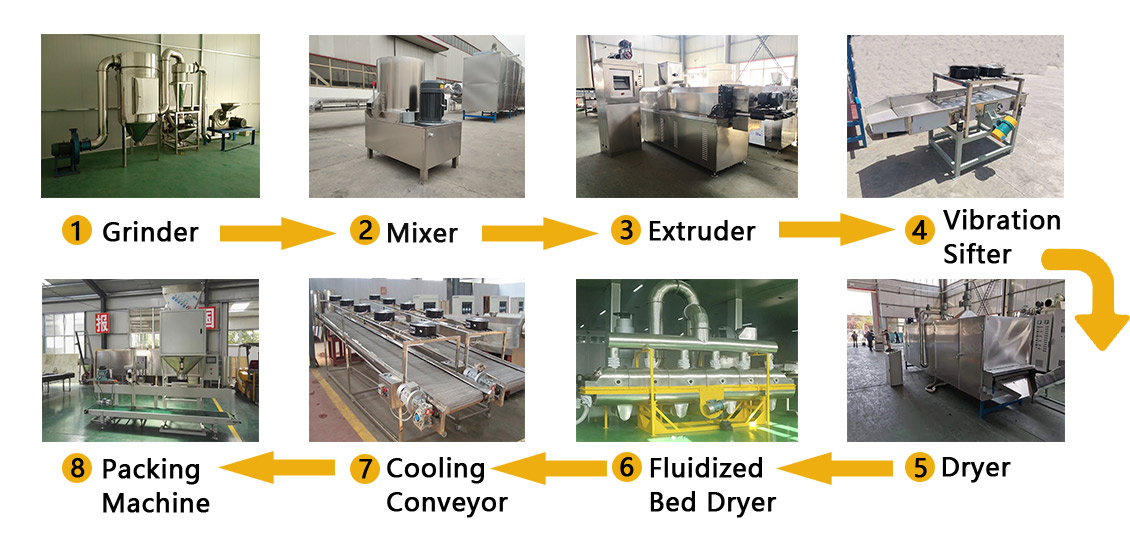

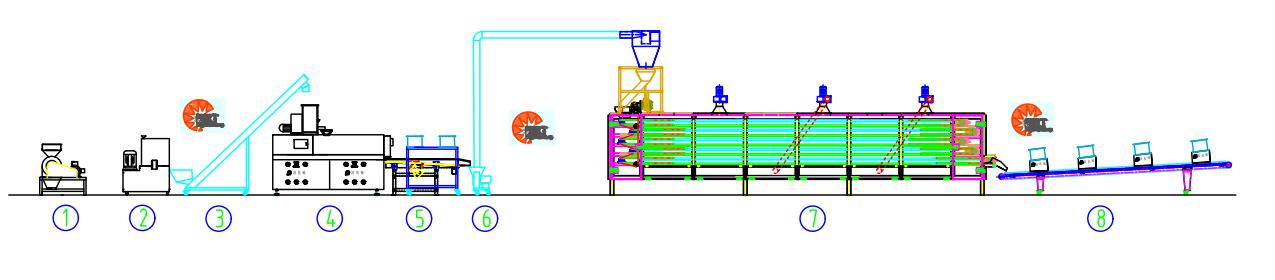

6 Flow Chart

Flow chart:Grider→Mixer→Screw conveyor→Extruder→Vibration cooling machine→Air conveyor→Dryer→Cooling conveyor

7 Product Advantages

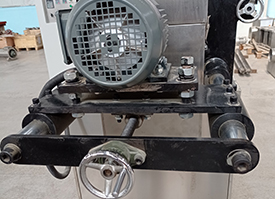

1.Artificial Rice Making Machinery Percent contact show control, considered operation, handy operation, components and electric powered powered factors and exclusive digital elements are determined world regularly occurring emblem, the quality of the laptop is assured. imported bearing institution, strong bearing capacity, prolonged provider life.

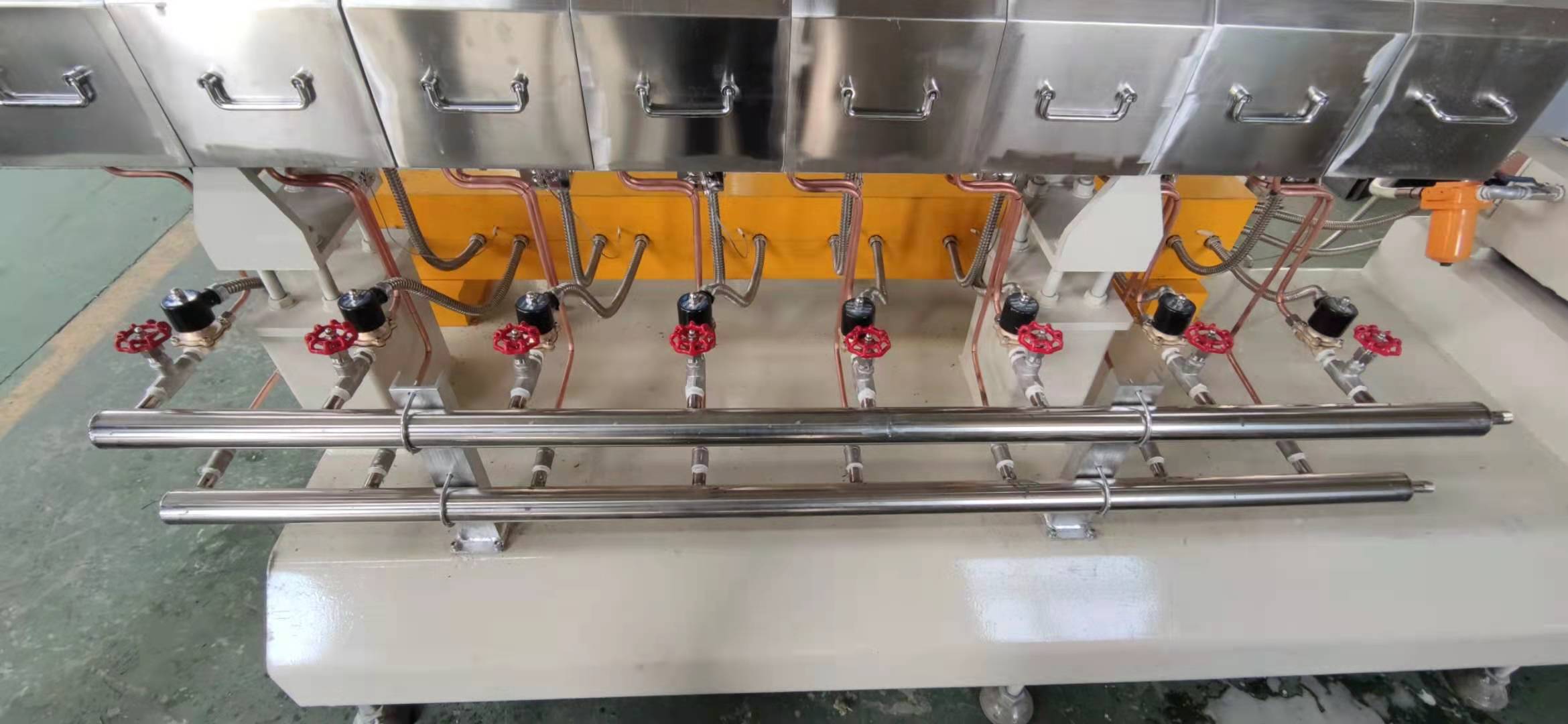

2.Artificial Rice Making Machinery barrel is geared up with a water injection device to greater meet the requirements of raw elements and best,also can have a giant range of uncooked fabric adoption,wider applicability of raw substances, can add a desire of dietary nutritional vitamins to furnish dietary rice with brilliant features.

3.Building block variety blended screw, can be blended freely consistent with high-quality uncooked factors and products,excessive-pace system metal cloth, hardness hrc≥sixty two, prolonged company lifestyles,specific rotary lowering diagram to make certain product consistency and floor smoothness.

4.Artificial Rice Making Machinery dryer makes use of in actuality insulated field, adopts indoors thermal circulation technique, excessive thermal performance, low strength intake.the dryer has unmarried-layer, 3-layer, 5-layer, and seven-layer ovens; a couple of constructions alongside with extended, reciprocating, and so on.; extra than one heating strategies: strength, steam, fuel/gas, to be had for selection, shopper customization, select the most fabulous device.

Send your message to us

Related News

Production Technology of Extruded Snack Food

2024-11-10

Daily Maintenance of Twin Screw Extruder

2024-10-28

Submitted successfully

We will contact you as soon as possible

Close