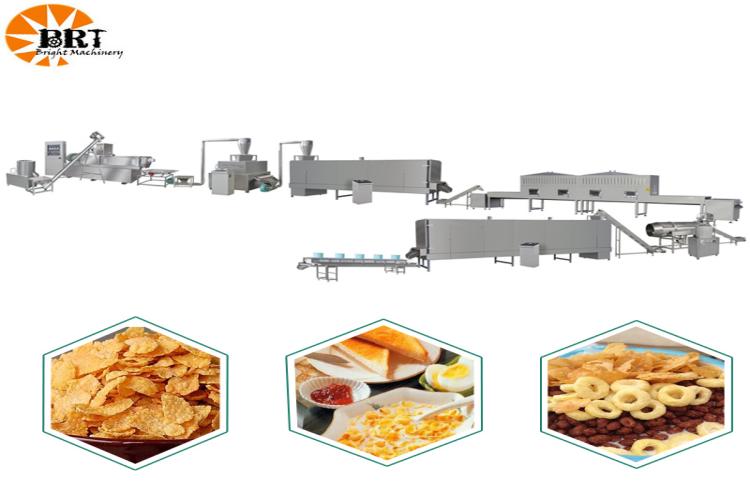

Automatic Corn Flakes Making Machine

Breakfast cereal production line adopts advanced puffing technology, all kinds of cereal raw materials after high temperature and high pressure treatment, instant puffing into crisp, nutritious breakfast cereal. The whole production line is composed of ingredients, mixing, expanding, drying, seasoning, cooling, packaging and other links, with a high degree of automation and fast production efficiency.

1 Ingredients: The ingredients of corn flakes are very important, seasonings to ensure a good taste, especially the requirements for corn raw materials, is directly related to whether to make high-quality corn flakes products, as well as the proportion of various nutrients, content.

2 Extrusion ripening molding: The extrusion ripening molding process of corn flakes is the key to producing high-quality corn flakes. This is the only way to make a dense, hard, and aromatic corn chip.

3 Cutting: The twin-screw extruder extrusion after the material cut into the size of the same granular material, the material is translucent.

4 Pre-drying: The material cut into the dryer for pre-drying, the surface after drying formed a certain tension, no longer adhere to each other, is conducive to the smooth progress of the press.

5 Pressing: The pressing process is also the key in the production of corn flakes, the requirements for the pressing machine are very high, the roll surface must have a high finish, the roll must be constant temperature.6 High temperature baking: Whether the corn chip product has a hard crisp, dense organizational structure, highlighting the unique flavor of corn, the baking process is crucial.

7 After the baking of corn chips after cooling is corn chip products, at present, there are a lot of corn chips for post-process processing, coated with sugar, salt stir-fry or coated with chocolate, mostly according to the taste of the market.

8 After spraying and seasoning, the product is baked again to stabilize the product form, and then enters the packaging section after cooling

The puffed breakfast cereal has a crisp taste and a tangy aroma, which makes people's appetite increase.

The combination of various cereal raw materials and nutritious ingredients makes breakfast cereals rich in protein, vitamins, minerals and other nutrients to meet the nutritional needs of the human body.

The breakfast cereal production line has a high degree of automation and fast production efficiency, which can quickly produce a large number of delicious and healthy breakfast cereals.

Health and environmental protection: The production line adopts advanced puffing technology, does not add any additives and preservatives, green environmental protection, so that consumers can rest assured.