Instant Rice Production Line

Lead Time: 15-25 days

Materials: stainless steel 304

Voltage: Customized, 110v-440v,50-60hz.

Core Components Brand: Siemens,Delta, Schneider, Baltur

Shipping: Support to sea freight, land and air freight

Service:

1 One year warranty, lifetime service

2 Local engineer on-site service available within 14 working days

Product Details

Instant Rice Production Line

1.Introduction

The usage of this approach gadget, the damaged rice (broken rice and fallen rice embryo) can be restored, restored or processed into rice grains which may be almost similar to everyday whole rice, or in line with the requirements of medical food regimen, some herbal vitamins inclusive of various sorts miscellaneous grains are mixed together in a fantastic percent to make excessive-vitamins rice and on the spot rice with the same cooking overall performance and cooking method (with taste) as normal rice.

The fortified nutritious rice production line is a food production gadget advanced and produced by manner of the organization according to the cutting-edge food vitamins wishes. the manufacturing system adapts to the general scenario of human beings's dietary strengthening remedy in modern-day society, meets human beings's necessities for nutritional balance, and has the benefits of excessive degree of automation and power saving. the production line can use numerous grains which includes rice, millet, black rice, buckwheat, and so on. as raw substances, add numerous nutrients, proteins and minerals for processing, squeeze, mature and shape in an extruder to regenerate new stronger nutrients rice, its eating approach is the same as herbal rice and it's miles less complicated and further reachable, both nutritious and healthy

2.Production Video

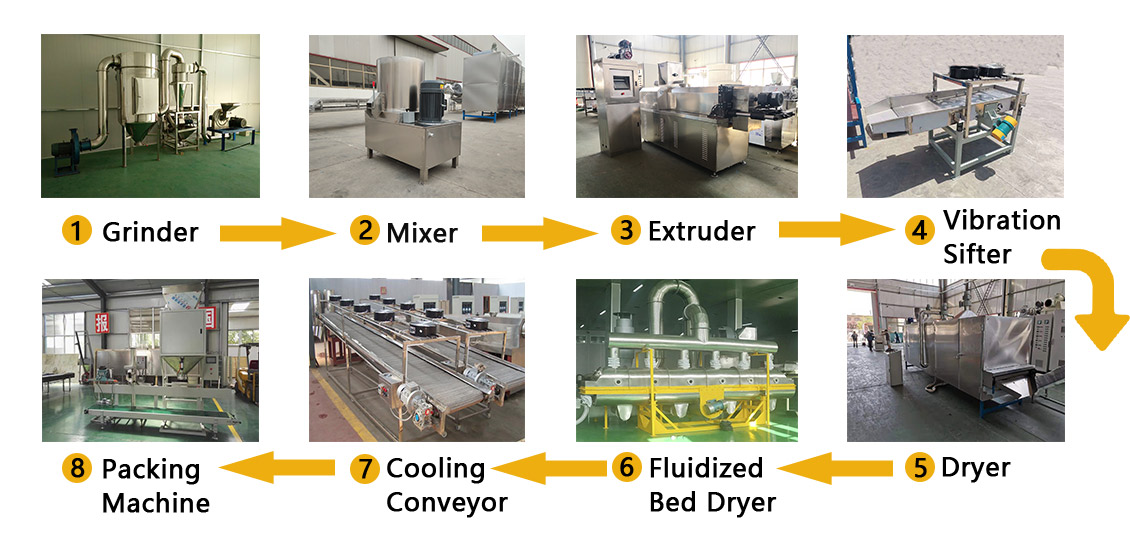

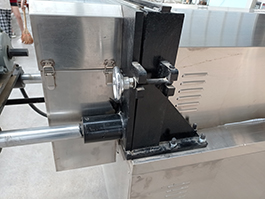

3.Machine Display

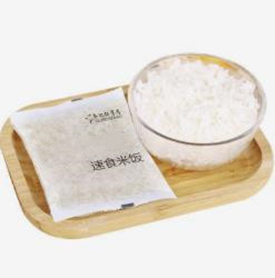

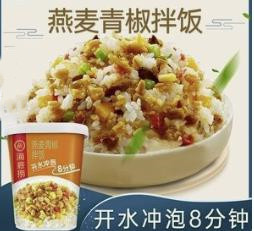

4.Samples

5.Technical Parameter

Model | Install power(kw) | Actuall consumption(kw) | Capacity | Size(mm) |

DSE-70 production line | 120 | 84-96 | 150-200 kg/h | 21000*1500*3000 |

DSE-75C production line | 150 | 105-120 | 250-300 kg/h | 24000*1500*3000 |

DSE-95C Production line | 490 | 342-392 | 400-500 kg/h | 32000*1500*3000 |

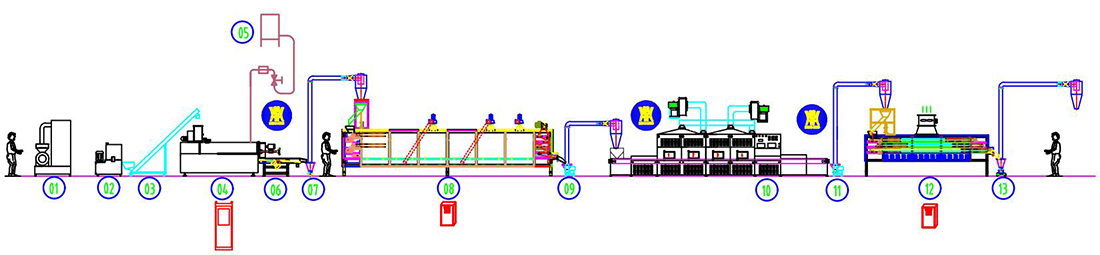

6.Flow Chart

Grider→Mixer→Screw conveyor→Extruder→Vibration cooling machine→Air conveyor→Dryer→Air conveyor→fluidized bed dryer→Air conveyor→Cooling machine→Cyclone

7.Product Advantages

1. PLC touch screen control,easy operation,precise control,Imported bearing set, strong carrying capacity and long service life,International famous parts and electric components,promise machine quality.

2. The barrel is equipped with a water injection device to better meet the requirements of raw materials and quality,also can have a larger range of raw material adoption,Wider applicability of raw materials, can add a variety of nutrients to produce nutritional rice with different functions.

3. Building block type combined screw, can be combined freely according to different raw materials and products,High-speed tool steel material, hardness HRC≥62, long service life,Unique rotary cutting design to ensure product consistency and surface smoothness.

4. The dryer uses fully insulated box, adopts internal thermal circulation method, high thermal efficiency, low energy consumption,The dryer has single-layer, three-layer, five-layer, and seven-layer ovens; multiple structures such as extended, reciprocating, etc.; multiple heating methods: electricity, steam, fuel/gas, available for selection, customer customization, choose the most suitable machine.

5. The instant rice can pour in hot water and eat directly,no need to boil,very convenient.double dryer heating process,remove the moisture of the produce as much as possible,better water Better absorption.

Send your message to us

Related News

Decrypt the Large Twin Screw Extruder

2024-12-20

What We Should to Know When Choose Pet Food

2024-12-11

Submitted successfully

We will contact you as soon as possible

Close