Oil Drilling Modified Starch Machines

Lead Time: 15-25 days

Materials: stainless steel 304

Voltage: Customized, 110v-440v,50-60hz.

Core Components Brand: Siemens,Delta, Schneider, Baltur

Shipping: Support to sea freight, land and air freight

Service:

1 One year warranty, lifetime service

2 Local engineer on-site service available within 14 working days

Product Details

Oil Drilling Modified Starch Machines

1.Introduction

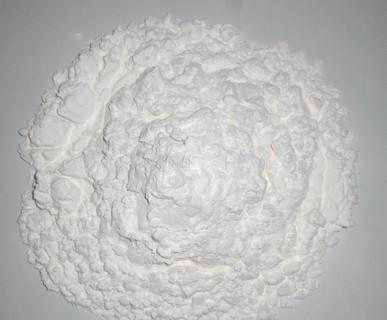

Modified starch is also called pre-gelatinized starch, is mainly made by corn starch and cassava starch. Through the process of mixing,extruding,drying,cooling and crushing, we could get the modified starch. The same production line can produce all kinds of modified starch . At the same time, the same modified starch can be matched with different machine production lines according to different capacity.

2.Production video

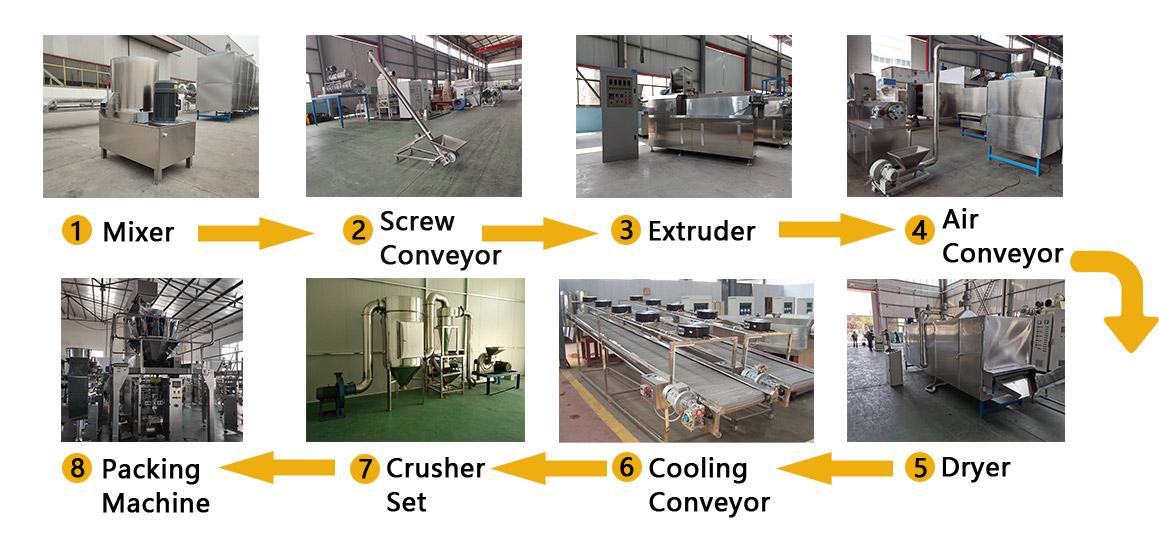

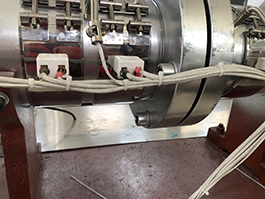

3.Machine display

4.Samples

5.Technical parameter

Model | Install power(kw) | Actuall consumption(kw) | Capacity | Size(mm) |

DSE-65 production line | 80 | 56-64 | 100-150 kg/h | 21000*1500*3000 |

DSE-70 production line | 116 | 82-93 | 200-250 kg/h | 21000*1500*3000 |

DSE-75 production line | 154 | 108-123 | 300-350 kg/h | 25000*1500*3200 |

DSE-85 production line | 194 | 137-156 | 400-500 kg/h | 25000*1500*3200 |

DSE-85S production line | 121(Steam dryer) | 85-97 | 600-800 kg/h | 28000*1500*3500 |

DSE-95S production line | 165(Steam dryer) | 115-132 | 1000-1800 kg/h | 28000*1500*3500 |

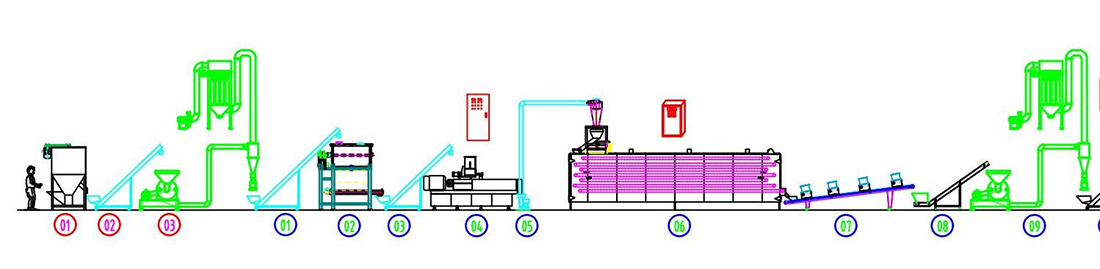

6.Flow chart

Stock Binr→Screw Conveyor→Crusher→Screw Conveyor→ Mixer→Screw Conveyor→Extruder→Air Conveyor→Dryer→Cooling Conveyor→Screw Conveyor→Crusher

7.Product advantages

1.It has a forced lubrication system and infiltrates the gear box, so that the transmission part of the extruder has a longer service life and improves the transmission efficiency of the extruder.

2.Using the frequency conversion speed regulation system, the feed speed, rotary cutting speed and the running speed of the main machine can be adjusted according to the specific production needs, with strong operability and more stable operation.

3.The extruder adopts twin screw, which is composed of feeding system, extrusion system, heating system, rotary cutting system and control system. The process is complete and it runs smoothly.

4.The main electrical accessories brands of the production line are diversified, and the brands of electrical accessories can be changed according to the actual needs of customers, including Schneider, Baltur, Delta, SKF, etc.

Send your message to us

Related News

Decrypt the Large Twin Screw Extruder

2024-12-20

What We Should to Know When Choose Pet Food

2024-12-11

Submitted successfully

We will contact you as soon as possible

Close