1. Adsorption properties and their applications (fillers) Starch can be used as a diluent (or filler) in feed additive products to fill and disperse active ingredients in feed additive products to increase their weight or volume, facilitate formulation molding and dispersion, and further make…

2023/03/10 11:54

How to Calculate the Protein Content in Feed and the Function of Protein in FeedHow to calculate the protein content in 100 kg feed1. Calculate the protein content in 100kg feed. Firstly, check the nutritional value table of feed to obtain the content of raw protein in feed.2. Take feed formula as…

2023/02/27 13:39

How to Choose Suitable Fish Feed and Fish Feed Machine1. Protein is the main nutritional index of fish compound feedThe protein content in the feed is one of the criteria to measure the nutritional level of the feed, but it does not mean that the higher the protein content, the higher the feed…

2023/01/31 14:52

Advantages of twin-screw extrusion extruder(1) The adaptability of raw materials is wider, and it can adapt to the processing of raw materials with high viscosity, low viscosity, high oil content, high moisture or viscosity, oily, very wet and other slippery materials in single screw (SSE).(2)…

2023/01/11 10:46

This year is a strong year, this year is also a fruitful year, and this year is a year of great significance for the company! Today is the 10th anniversary of the establishment of the company. At the celebration site, suppliers and friends from all over the world came to congratulate, and the…

2022/12/30 10:47

Aquatic extruded feed processing technologyI. Processing technology of extruded fish feed1 Squeeze the puffed fish Extrusion curing is accomplished by a combination of water, pressure, temperature and mechanical shear. Extrusion curing, the temperature in the boring can reach 90 ~ 200℃,…

2023/01/05 13:42

How to Produce the Fortified Rice?Artificial rice is made of broken rice and rice flour, which can be added with natural grains, fruits, vegetables, seafood, etc., and can also be added with vitamins, minerals and trace elements and other essential nutrients for human body. Artificial rice is…

2022/12/26 16:21

Aquatic extruded feed processing technologyI. Processing technology of extruded fish feed1 Squeeze the puffed fish Extrusion curing is accomplished by a combination of water, pressure, temperature and mechanical shear. Extrusion curing, the temperature in the boring can reach 90 ~ 200℃,…

2023/01/05 13:42

The kinds of fish feed have long long past through a technique from uncooked to cooked, from shallow processing to deep processing, from the original fish and shrimp overwhelmed right now to feeding, to the later matured pellet feeding, to the modern nutrient ratio clinical feeding. the extruded…

2022/12/15 15:52

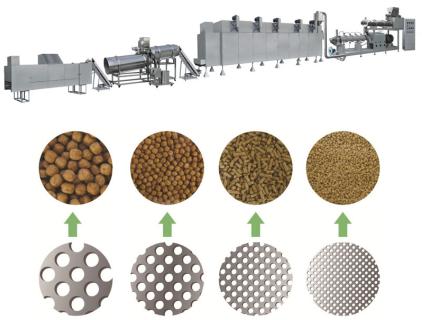

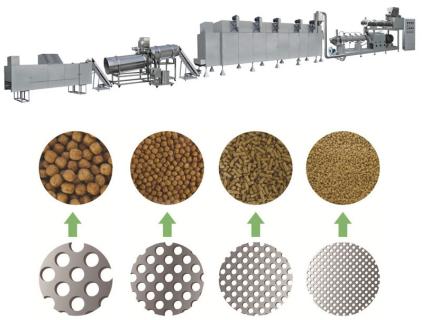

The main factors affecting the final moisture content of feed products are: the moisture content of the feed material itself, the moisture change in the crushing stage, the amount of liquid added in the mixing stage, the moisture content of the steam, the level of tempering, the die hole size and…

2022/12/13 09:34

First of all, we take the production of aquatic feed as an example, according to the material and purpose of the expansion from the structure of the single screw extruder and twin screw extruder,In general:--- Single screw extruder: suitable for processing all kinds of raw materials and common…

2022/12/10 18:08

Expanded/Puffing Feed Introduction:The expanded feed is a kind of puffy and porous feed formed by expanding the feed. Double screw fish feed extruder extruding is a processing technology that depressurizes the material after high temperature and high pressure treatment and changes some physical and…

2022/11/30 09:41

Submitted successfully

We will contact you as soon as possible

Close