Nutritional Powder Extruder

Nutritional powder extruder with rice, corn, oats, buckwheat, wheat bran, beans and other grains as raw materials, automatic assembly line to complete raw material mixing, extrudation, drying, dust-free crushing, proportional mixing, weighing and packaging and other technological processes, compared with the traditional manual frying method, The raw materials can be processed more widely, the production efficiency is higher, the product quality is stable, the process control can be realized; Nutritional powder extruder can also strengthen nutrients or functional raw materials, the production of a variety of functional nutrition and health powder, such as: "cereal health powder", "red dates and lotus seed soup", "black sesame paste", "buckwheat flour", "oat flour," etc.

Lead Time: 15-25 days

Materials: stainless steel 304

Voltage: Customized, 110v-440v,50-60hz.

Core Components Brand: Siemens,Delta, Schneider, Baltur

Shipping: Support to sea freight, land and air freight

Service:

1 One year warranty, lifetime service

2 Local engineer on-site service available within 14 working days

Product Details

1.Introduction

Nutritional powder refers to grains as the predominant uncooked substances (corn, rice, millet, wheat, oats, yam, konjac, etc., and quite a number beans such as black beans, pink beans, barley, black sesame, etc.), with greens and fruits , Eggs, meat and different non-compulsory ingredients, including calcium, phosphorus, iron and different minerals and vitamins, etc. via the extrusion procedure to gelatinize the cereal starch, and the protein is matured, and processed into a new product that is handy to eat, tastes strong, and nutritious. Times dietary complement food. Collectively referred to as dietary powder. According to exceptional product formulas, dietary powder consists of crimson bean and barley powder, yam powder, total grain powder, five-grain meal alternative powder, etc.

Nutritional powder extruder line can also strengthen nutrients or functional raw materials, the production of a variety of functional nutrition and health powder, such as: "cereal health powder", "red dates and lotus seed soup", "black sesame paste", "buckwheat flour", "oat flour," etc.

2.Production Video

3.Machine Display

4.Samples

5.Technical Parameter

Model | Install power(kw) | Actuall consumption(kw) | Capacity | Size(mm) |

DSE-65 production line | 80 | 56-64 | 100-150 kg/h | 21000*1500*3000 |

DSE-70 production line | 116 | 82-93 | 200-250 kg/h | 21000*1500*3000 |

DSE-75 production line | 154 | 108-123 | 300-350 kg/h | 25000*1500*3200 |

DSE-85 production line | 194 | 137-156 | 400-500 kg/h | 25000*1500*3200 |

DSE-85S production line | 121(Steam dryer) | 85-97 | 600-800 kg/h | 28000*1500*3500 |

DSE-95S production line | 165(Steam dryer) | 115-132 | 1000-1800 kg/h | 28000*1500*3500 |

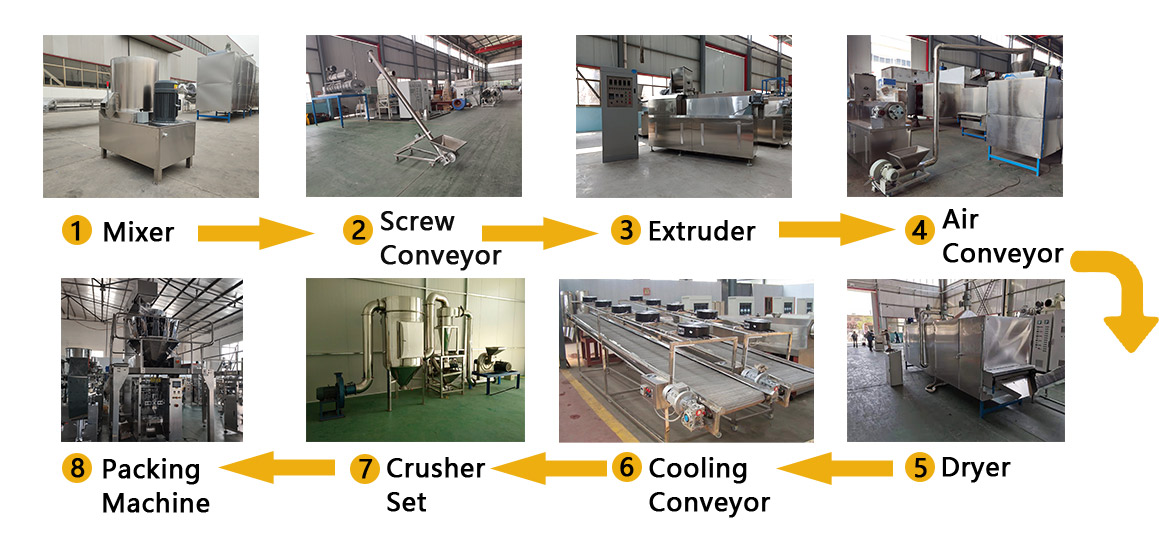

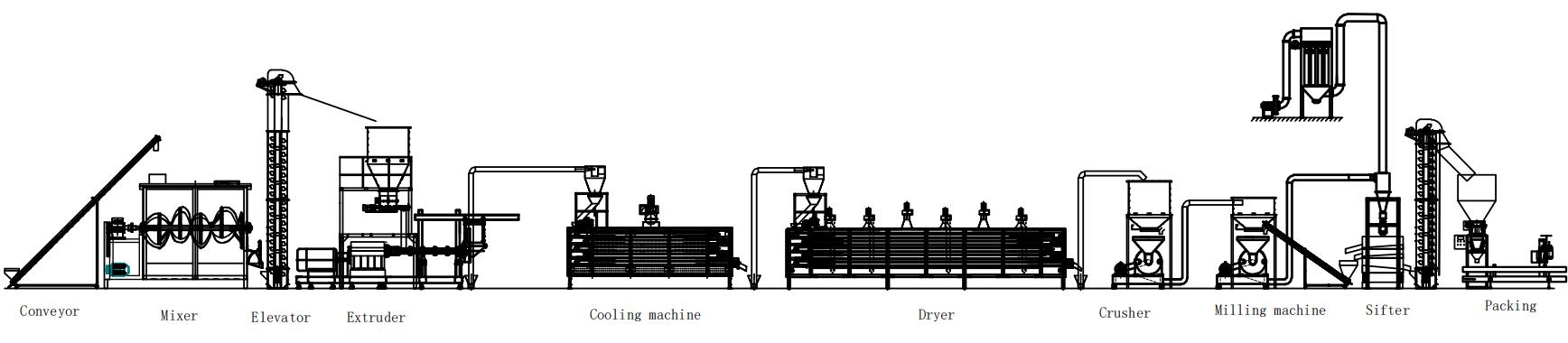

6.Flow Chart

Screw conveyor→Mixer→Bucket elevator→Extruder→Air conveyor→Cooling machine→Air conveyor→Dryer→Air conveyor→Crusher set→Sifter→Elevator→Packing machine

7.Product Advantages

1. Nutritional powder extruder using rice, corn, beans and other grains as raw materials, through extrusion, drying, crushing and mixing, a variety of nutritional powders can be produced, such as baby rice powder, sesame paste and soybean powder.

2.Nutritional powder extruder line automatically completes the process flow from the start of feeding, with simple operation, no dust leakage, sanitation and energy saving. It can be easily mixed with various raw materials and nutrients.

3. Nutritional powder extruder integrates mixing, extruding, drying,cooling, milling and packaging. Nutritional powder extruder line does not require boilers, and the production process is simplified, efficient, and environmentally friendly.

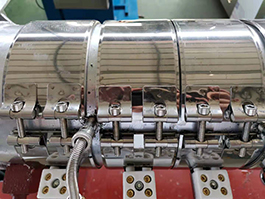

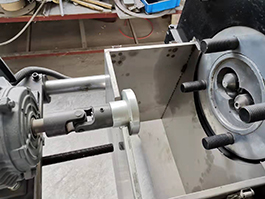

4. Nutritional powder extruder adopts domestic high-efficiency twin-screw extrusion technology, and the screw segmented combined structure can meet the needs of different grain raw materials. The raw materials can be rice flour and corn flour as a single material, or a mixture of them.

Send your message to us

Related News

Decrypt the Large Twin Screw Extruder

2024-12-20

What We Should to Know When Choose Pet Food

2024-12-11

Submitted successfully

We will contact you as soon as possible

Close