Nutritional Powder Baby Food Process Line

With the growing enchancment of people's dwelling standards, fitness care merchandise and dietary powder have step by step entered lots of households in the shape of gifts. People who have come out of the typical food regimen shape start to seem for purposeful meals that are conducive to fitness and sturdiness after they have adequate to eat. Nutrition is additionally broadly used. My company's nutritional powder baby food process line on the foundation of absorbing overseas technology, its very own lookup and improvement of a set of nutritional powder baby food process line, it will be the typical technique into uncooked grain making use of excessive temperature, excessive stress extrusion, make its uncooked grain in the starch, so greater conducive to the absorption of human body, and the dietary price is greater than the normal processing technology.

Lead Time: 15-25 days

Materials: stainless steel 304

Voltage: Customized, 110v-440v,50-60hz.

Core Components Brand: Siemens,Delta, Schneider, Baltur

Shipping: Support to sea freight, land and air freight

Service:

1 One year warranty, lifetime service

2 Local engineer on-site service available within 14 working days

Product Details

Nutritional Powder Baby Food Process Line

1.Introduction

Jinan Bright Machinery company improved nutritional powder baby food process line is on the basis of absorbing foreign technology, developed by a set of automated nutritional powder baby food process line, it will be the traditional method into raw grain making use of high temperature, high pressure extrusion, make its raw grain in the starch modified, which facilitates the absorption of human body, and the nutritional value is higher than the traditional processing technology. Nutritional powder baby food process line is mainly made of all kinds of grains as the main raw materials, and properly added with all kinds of nutrients necessary for human daily through deep processing of ingredients, and can also be processed completely naturally.

Nutritional powder baby food process line has the characterictic of high automation, strong stability, simple operation, high yield, short process time and so on, and effectively improves the disadvantages of the original tradition. It is a new type of high efficiency nutrition rice noodle production line.

Nutritional powder baby food process line can be used to produce all kinds of baby rice flour, sesame paste, walnut paste products

2.Production Video

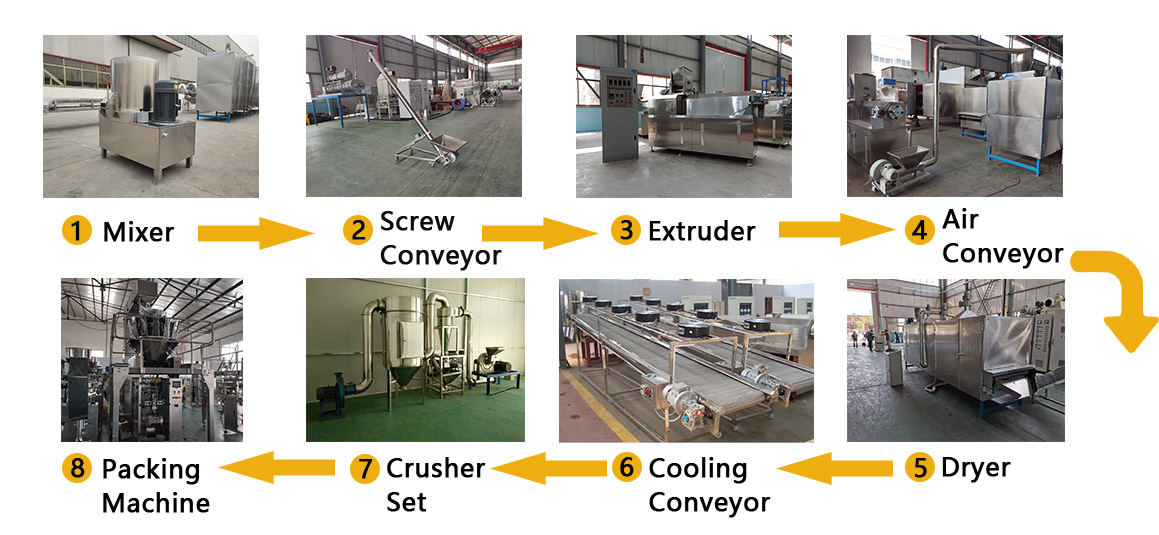

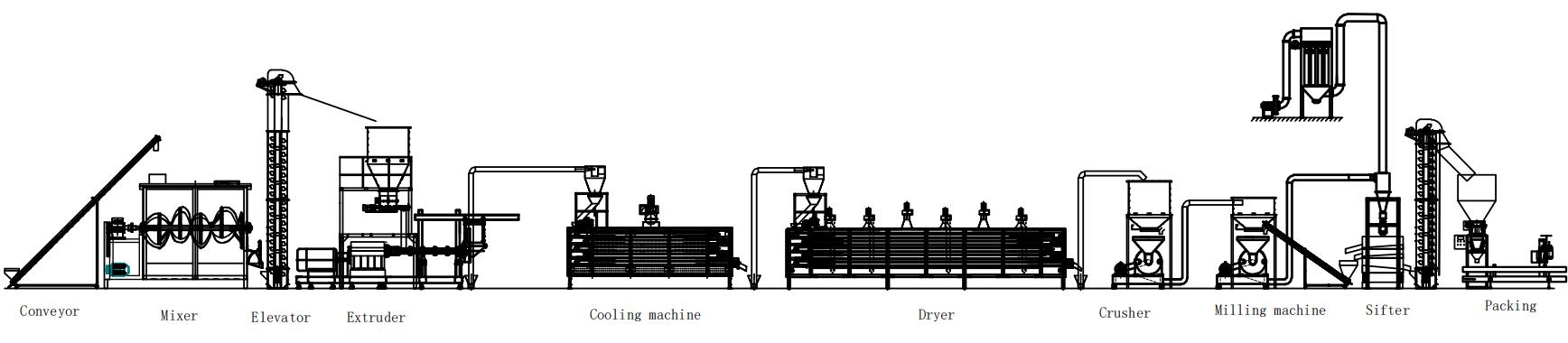

3.Machine Display

4.Samples

5.Technical Parameter

Model | Install power(kw) | Actuall consumption(kw) | Capacity | Size(mm) |

DSE-65 production line | 80 | 56-64 | 100-150 kg/h | 21000*1500*3000 |

DSE-70 production line | 116 | 82-93 | 200-250 kg/h | 21000*1500*3000 |

DSE-75 production line | 154 | 108-123 | 300-350 kg/h | 25000*1500*3200 |

DSE-85 production line | 194 | 137-156 | 400-500 kg/h | 25000*1500*3200 |

DSE-85S production line | 121(Steam dryer) | 85-97 | 600-800 kg/h | 28000*1500*3500 |

DSE-95S production line | 165(Steam dryer) | 115-132 | 1000-1800 kg/h | 28000*1500*3500 |

6.Flow Chart

Screw conveyor→Mixer→Bucket elevator→Extruder→Air conveyor→Cooling machine→Air conveyor→Dryer→Air conveyor→Crusher set→Sifter→Elevator→Packing machine

7.Product Advantages

1. Using rice, corn, beans and other grains as raw materials, through extrusion, drying, crushing and mixing, a variety of nutritional powders can be produced, such as baby rice powder, sesame paste and soybean powder.

2. The nutritional powder baby food process line automatically completes the process flow from the start of feeding, with simple operation, no dust leakage, sanitation and energy saving. It can be easily mixed with various raw materials and nutrients.

3. Nutritional powder baby food process line integrates mixing, extruding, drying,cooling, milling and packaging. It does not require boilers, and the production process is simplified, efficient, and environmentally friendly.

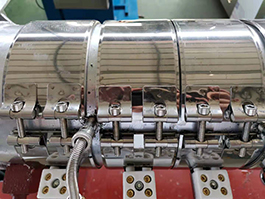

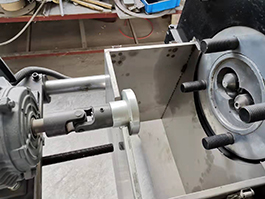

4. The extruder adopts domestic high-efficiency twin-screw extrusion technology, and the screw segmented combined structure can meet the needs of different grain raw materials. The raw materials can be rice flour and corn flour as a single material, or a mixture of them.

Send your message to us

Related News

Decrypt the Large Twin Screw Extruder

2024-12-20

What We Should to Know When Choose Pet Food

2024-12-11

Submitted successfully

We will contact you as soon as possible

Close