Pet Chews Machine

Lead Time: 15-25 days

Materials: stainless steel 304

Voltage: Customized, 110v-440v,50-60hz.

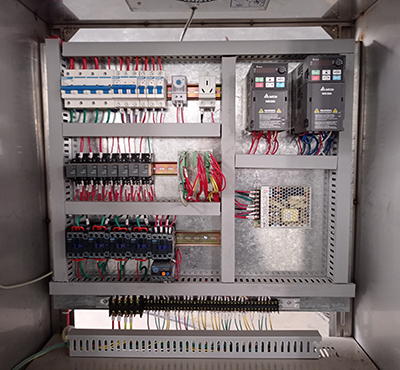

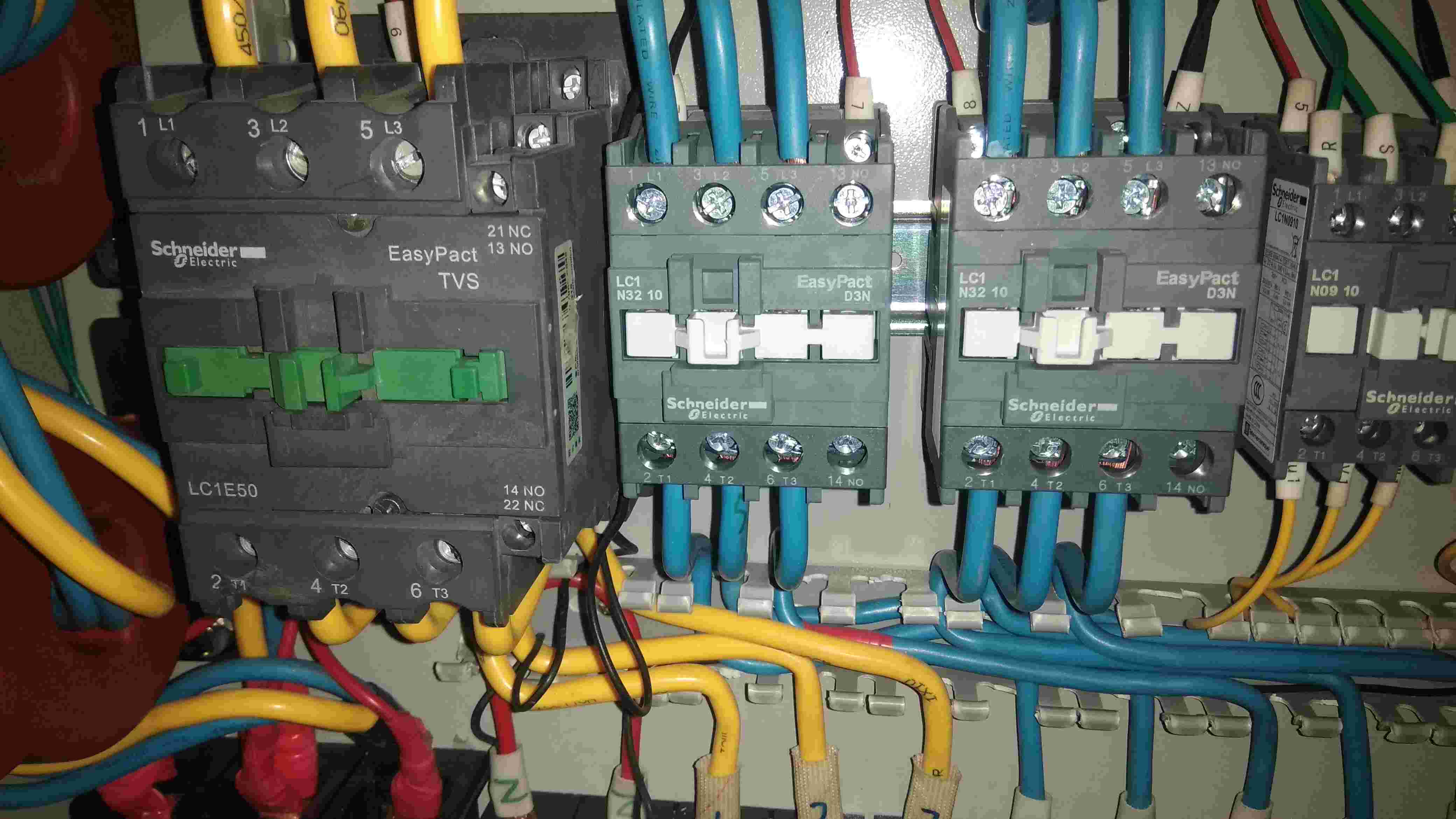

Core Components Brand: Siemens,Delta, Schneider, Baltur

Shipping: Support to sea freight, land and air freight

Service:

1 One year warranty, lifetime service

2 Local engineer on-site service available within 14 working days

Product Details

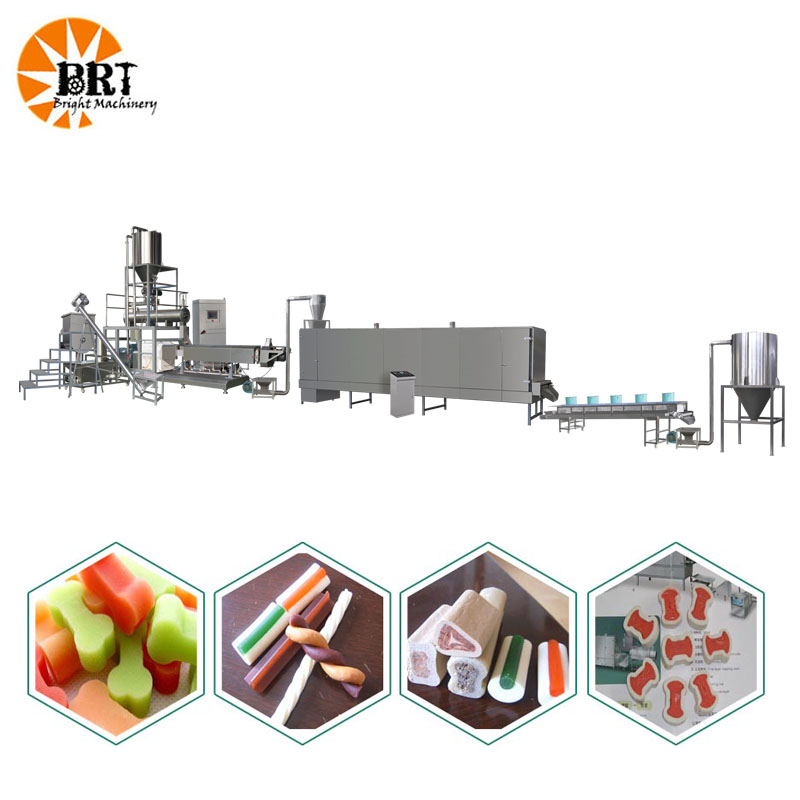

Pet Chews Machine

1.Introduction

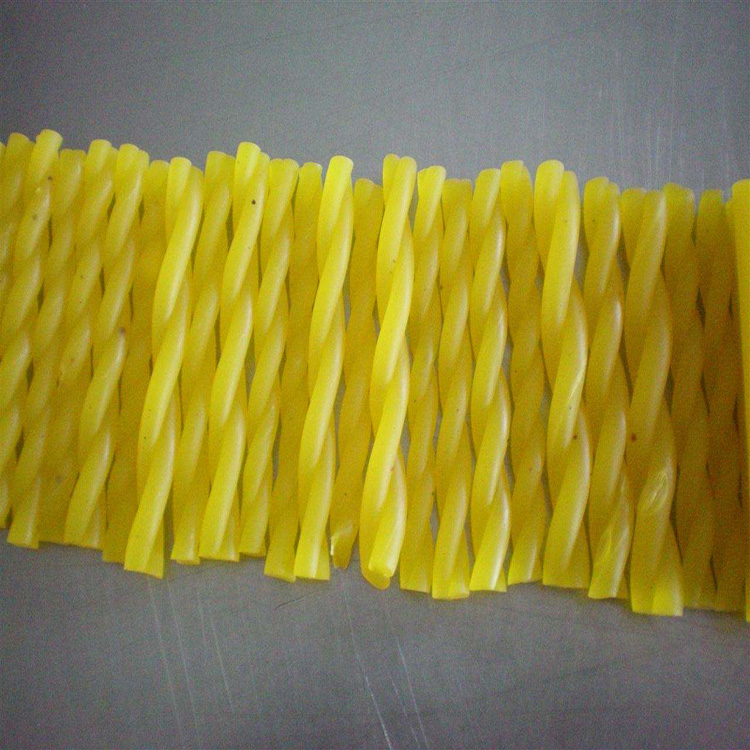

Pet chews production line may additionally want to produce all kinds of dog chews, as an instance, unmarried shade and double-shade dog treat, twist treats and so on

Dog chews snacks are a type of snacks in particular designed and developed for pet puppies to meet the chewing and biting needs of puppies as they grow up. at the identical time, canine chews can keep oral fitness and save you the formation of dental plaque and calculus. typically it made into bone and strip form, suitable for the characteristics of puppies even as playing and biting.

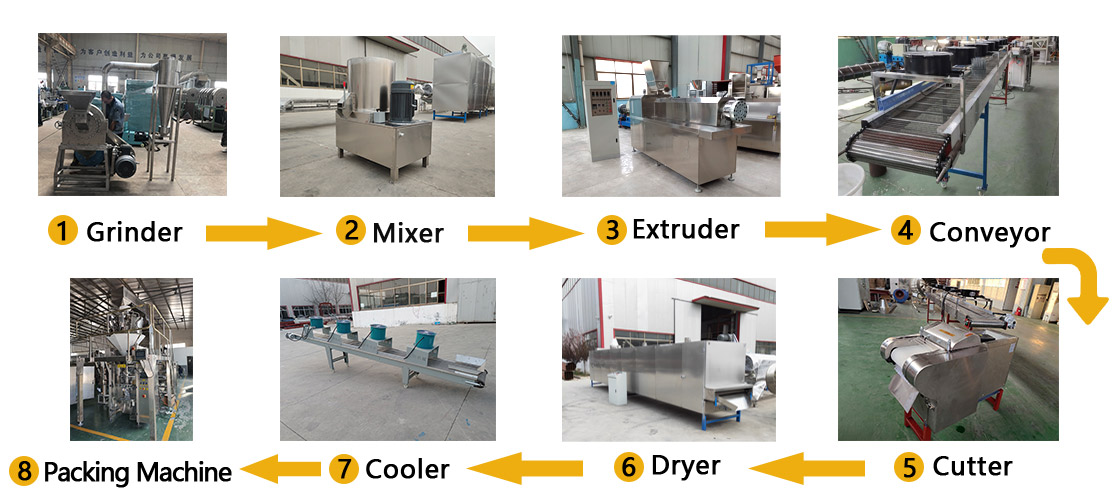

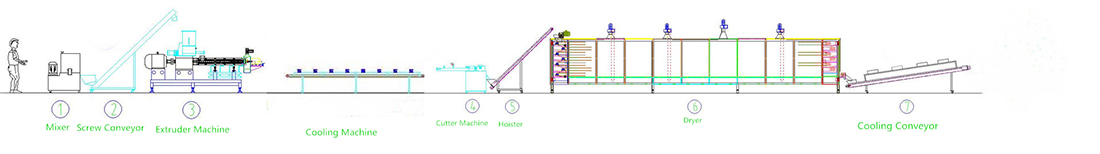

The primary machine of domestic dog chew manufacturing line: mixer, screw conveyor, extruder, cooling conveyor, cutter, high hoister, dryer, cooling conveyor

2.Production video

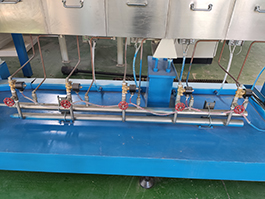

3.Machine display

4.Samples

5.Technical parameter

Model | Capacity/output | Installed Power | Power Consumption | Dimension |

SSE100 Dog Chew Production Line | 100-150kg/h | 134kw | 108kw | 27*3*2.5m |

DSE75F Dog Chew Production Line | 200-300kg/h | 200kw | 160kw | 30*3*2.5m |

6.Flow chart

Mixer→Screw Conveyor→Extruder→Cooling Machine→Cutter→Hoister→Dryer→Cooling Conveyor

7.Product advantages

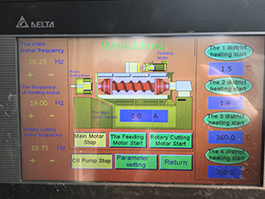

1. The extruder adopts advanced frequency converter speed regulation technology, so that the equipment has strong power, more stable operation, more electricity saving.

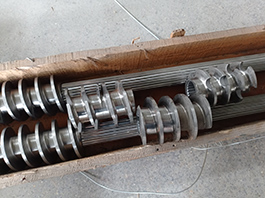

2. The screw adopts alloy steel nitriding treatment, longer life of the screw, individual equipment adopts building block combination structure, can be arbitrarily combined according to different needs

3. Visual automatic temperature control system, to make the temperature control more intuitive, more accurate parameters. Optional Delta or Siemens brand PLC control system

4. Equipped with water cooling system, more accurate temperature control, better product molding

5. New high strength Gear box, made of QT400, aging treatment and good stability; oil filter and oil cooler to extend the life of the gearbox

Send your message to us

Related News

Decrypt the Large Twin Screw Extruder

2024-12-20

What We Should to Know When Choose Pet Food

2024-12-11

Submitted successfully

We will contact you as soon as possible

Close