Corn Puff Snack Food Extruder

Corn Puff Snack Food Extruder undertake corn, rice, wheat, oat, barley and so on as factors to make puffed snack. Through frication of screw and barrel, the grains are cooked in the extruder. Forming is at the die face cutter. The product form is determined thru a combination of the die aperture, collectively with ball, tube, stick, ring, fruit loop, star, wheel and flower etc.

Lead Time: 15-25 days

Materials: stainless steel 304

Voltage: Customized, 110v-440v,50-60hz.

Core Components Brand: Siemens,Delta, Schneider, Baltur

Shipping: Support to sea freight, land and air freight

Service:

1 One year warranty, lifetime service

2 Local engineer on-site service available within 14 working days

Product Details

1 Introduction

The Corn Puff Snack Food Extruder makes powdered uncooked factors which consist of corn flour into puff snack by means of the laptop of mixing,puffing,drying,flavoring and cooling. the equal manufacturing line can produce puff snacks of a fluctuate patterns and sizes. at the equal time, the equal puff snack can be matched with computer pc manufacturing traces in step with particular potential.

2 Production Video

3 Machine Display

4 Samples

5 Technical Parameter

Model | Capacity/output | Installed Power | Power Consumption | Dimension |

100-150kg/h | 120kw | 96kw | 26*3*2.2m | |

DSE65F Puff Snack Production Line | 100-150kg/h | 124kw | 100kw | 26*3*2.2m |

DSE70 Puff Snack Production Line | 200-250kg/h | 164kw | 132kw | 28*3*2.2m |

DSE70F Puff Snack Production Line | 200-250kg/h | 130kw | 104kw | 26*3*2.2m |

DSE85 Puff Snack Production Line | 300-500kg/h | 270kw | 216kw | 32*3*2.2m |

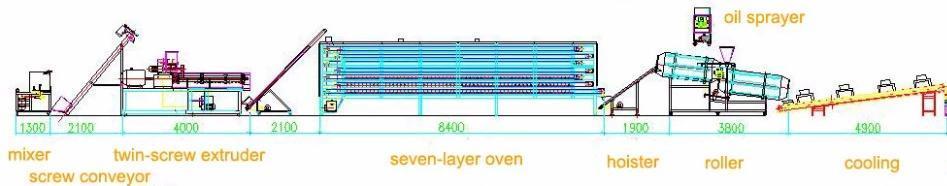

6 Flow Chart

Mixer→Screw Conveyor→Extruder→Air Conveyor→Dryer→Hoister→Flavoring System→Cooling Conveyor

7 Product Advantage

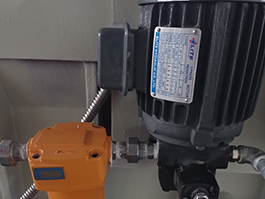

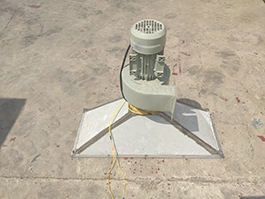

1.Corn Puff Snack Food Extruder Adopt Siemens motor, Delta inverter, Schneider Omron ABB electrical components, the world's daily brands, safe, reliable and durable, can efficiently manipulate the motor tempo in accordance to the united states of the us of the product, hinder consumption.

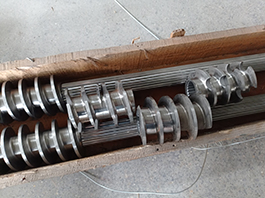

2.The screw material is high-speed alloy steel, carburized, with hardness up to HRC 55-65, immoderate put on resistance, immoderate hardness, notable toughness, optionally on hand 38CrMoAl, 12CrMoV, W6Mo5Cr4V2 material, prolonged corporation life. Some Corn Puff Snack Food Extruder are geared up with a combination screw, which has wider applicability of raw materials. The screw mixture strategy can be adjusted in accordance to splendid products, and one Extruder can be used for greater than one purposes.

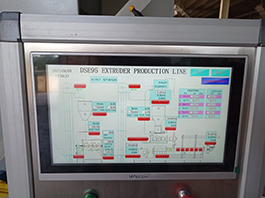

3.Corn Puff Snack Food Extruder's major motor, rotary lowering motor and feeding motor are all managed with the beneficial beneficial useful resource of frequency conversion, which can apprehend handy start and efficiently guard the motor, and can alter the tempo in accordance to the product recognition to produce larger fantastic products; geared up with PLC contact show off exhibit show manipulate system, equipment temperature and The tempo adjustment is greater digital and the manipulate is expanded precise.

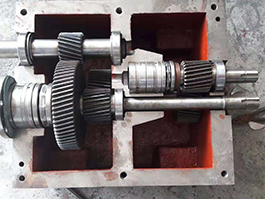

4.Corn Puff Snack Food Extruder the use of a new shape of box, the container material QT400, relevant stability. Gear cloth 20CrNiMoA, carburizing and quenching, hardness HRC58-62, immoderate precision, low noise, prolonged provider life; the use of Japanese NSK, SKF bearings, immoderate precision, prolonged life, tightly closed performance; oil pump motor, compelled inner circulation lubrication; condenser, avert The floor temperature of gears and bearings will increase the organisation life; the filter cleans the impurities in the oil, improves the lubrication have an influence on and prolongs the company life.

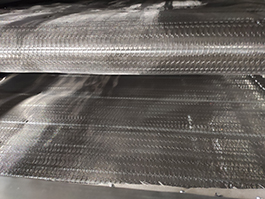

5.According to the suitable situation, Corn Puff Snack Food Extruder unique electrical power sources, electricity, gasoline oil, gas, steam can be used to retailer manufacturing costs; geared up with circulating followers and dehumidification followers to promote warmness circulation, do away with water vapor, and enhance drying efficiency; 304 stainless steel mesh cloth and mesh are used. belt to make tremendous product quality; adjustable taking walks speed, adjust drying time in accordance to splendid products, immoderate efficiency.

Send your message to us

Related News

Decrypt the Large Twin Screw Extruder

2024-12-20

What We Should to Know When Choose Pet Food

2024-12-11

Submitted successfully

We will contact you as soon as possible

Close